Welcome to Our Company -

-

Our Products

- Laboratory Chemicals

- 2 -Amino-6-bromo-4-methylbenzo[d]thiazole

- O-Bromoaniline Chemicals

- Solar Glycol

- Formic Acid

- 1-Chlorobutane For Liquid Chromatography

- 3-3-Dimethylbutyraldehyde Chemicals

- Ethyl--D-Glucuronide Chemicals

- Pure N-Heptane Chemical

- Nitric Acid

- Liquid Nitric Acid

- Tert Butyl Methyl Ether

- HACH Chemicals

- 1-Butanol Chemical

- HMB Calcium

- Zinc Sulphate Solution

- Acetonitrile Hypergrade For LC-MS

- Acetonitrile Sigma Aldrich

- Silver Iodide

- 1-Chlorobutane Chemicals

- Neutragel Neo Chemical

- Acetone Chemicals

- 3-Octanone Chemicals

- Ginkgolide C Chemicals

- Goldbio Chemicals

- 4-Aminophenol Acetaminophen RCK

- 1-Amino-3-(benzyloxy)cyclobutanecarboxylic acid hydrochloride

- 4-Aminopyrrolo[2,1-f][1,2,4]triazine-5-carboxylic acid

- 2-Amino-2- methylpropanenitrile

- Specialty Chemicals and Research Chemicals

- Hazardous and Non Hazardous Bulk Chemicals

- Aldehydes

- 3-Allylsalicylaldehyde 95%

- 1-Allyl-1h-pyrrole-2-carbaldehyde 95%

- 1-Allyl-1h-pyrazole-4-carbaldehyde 95%

- 3-Allyl-4-(2-propyn-1-yloxy)benzaldehyde 95%

- 4-(Allyloxy)-3-methoxybenzaldehyde 95%

- 4-(Allyloxy)-3-iodo-5-methoxybenzaldehyde 95%

- 4-(Allyloxy)-3-ethoxybenzaldehyde 95%

- 4-(Allyloxy)-3-chloro-5-methoxybenzaldehyde 95%

- 4-(Allyloxy)-2-chloro-5-methoxybenzaldehyd 95%

- 4-(Allyloxy)-3-chloro-5-ethoxybenzaldehyde 95%

- 2-(2-Hydroxyethoxy) Acetaldehyde 95%

- 4 - Acetamidobenzaldehyde 95%

- Gossypol-acetic Acid 95%

- Acetic acid 2-formyl-quinolin-8-yl Ester

- 3-Formylphenyl Acetate 98%

- 5-Bromo-4-formyl-2-methoxyphenyl Acetate 98%

- 4-Acetoxy-3,5-dimethoxybenzaldehyde 97%

- Acetylferulic Acid 95%

- 5-Acetoxymethyl-2-furaldehyde 98%

- 4-Acetoxy-4-methyl-1-pentanal 95%

- 2 - Acetylbenzaldehyde

- 3-Acetylbenzaldehyde 98%

- 4 Acetylbenzaldehyde 96%

- 4 Acetyl-biphenyl-4-carbaldehyde 95%

- N-Acetyl-D-Galactosamine 95%

- N-Acetyl-D-glucosamine 96%

- N-Acetylindole-3-carboxaldehyde 98%

- N-Acetyl-D-Mannosamine 97%

- 5-Acetyl-2-methoxybenzaldehyde 95%

- 4-Acetyl-1-methyl-1h-pyrrole-2-carbaldehyde 95%

- N-Acetyl-Muramic Acid 95%

- 1-(3-Acetylphenyl)-2,5-dimethyl-1h-pyrrole-3 Carbaldehyde

- 5-(4-Acetyl-phenyl)-furan-2-carbaldehyde 95%

- 1-(4-Acetylphenyl)-1h-pyrrole-2-carbaldehyde 95%

- 4-(4-Acetylpiperazin-1-yl)benzaldehyde 95%

- 1-Acetylpiperidine-4-carbaldehyde 95%

- 4-Acetyl-1h-pyrrole-2-carbaldehyde 98%

- 1-acetyl-1H-pyrrolo[2,3-b]pyridine-3 Carbaldehyde

- Acetylspiramycin 95%

- 5-Acetylthiophene-2-carbaldehyde 95%

- 5-Acetylthiophene-3-carbaldehyde 95%

- 3-Acetyl-2,4,6-trimethylbenzaldehyde 95%

- 3-(1-Adamantyl)-4-hydroxy-5-methoxybenzaldehyde 95%

- 3-(1-Adamantyl)-2-hydroxy-5-methylbenzaldehyde 95%

- 3-(1-Adamantyl)-1-phenyl-1h-pyrazole-4- carbaldehyde

- Adipaldehyde 1M in Water

- Alcaftadine 95%

- Ald-ch2-peg8-azide 95%

- Ald-ch2-peg10-t-butyl ester 95%

- Ald-ch2-peg4-ch2co2tbu 95%

- Aldehydo-D-glucose; keto-D-fructose 95%

- Ald-peg3-azide 95%

- Ald-peg1-t-butyl ester 96%

- Ald-peg4-t-butyl ester 95%

- Ald-peg5-t-butyl ester 95%

- Ald-peg5-t-butyl Ester

- Ald-peg4-nhs ester 95%

- Ald-peg4-pfp 95%

- Ald-ph-peg2-acid 95%

- Ald-Ph-PEG4-acid 95%

- Ald-ph-peg6-acid 95%

- Ald-ph-peg3-amine 95%

- Ald-ph-peg2-amine tfa salt 95%

- Ald-ph-peg2-t-butyl Ester

- Ald-ph-peg2-t-butyl Ester

- Ald-ph-peg4-t-butyl Ester

- Ald-ph-peg6-t-butyl Ester

- Ald-ph-peg2 nhboc

- Ald-ph-peg3-nh boc

- Ald-ph-peg3-o-nh boc

- Ald-ph-peg2 nhs

- All-trans Retinal

- 3-Allyl-4-(allyloxy)benzaldehyde 95%

- 3-Allyl-4-(allyloxy)-5 ethoxybenzaldehyde

- 3-Allyl-4-(allyloxy)-5 methoxybenzaldehyde

- 3-Allyl-4-butoxy-5 methoxybenzaldehyde

- -[(2E)-3-Allyl-4-chloro-5-formyl-1,3-thiazol-2(3h)-ylidene]thiophene-2-sulfonamide 95%

- 3-Allyl-4-(allyloxy)-5-methoxybenzaldehyde 95%

- 3-Allyl-4-butoxy-5-methoxybenzaldehyde 95%

- N-[(2E)-3-Allyl-4-chloro-5-formyl-1,3-thiazol-2(3h)-ylidene]thiophene-2-sulfonamide 95%

- 2-(Allyloxy)-5-chlorobenzenecarbaldehyde 95%

- 4-(Allyloxy)-2-chloro-5-ethoxybenzaldehyde 95%

- 3-Allyl-4,5-diethoxybenzaldehyde 95%

- 1-Allyl-2,3-dihydro-1h-indole-5 carbaldehyde

- 3-Allyl-4,5-dimethoxybenzaldehyde 95%

- 1-Allyl-3,5-dimethyl-1h-pyrazole-4 carbaldehyde

- 3-Allyl-4-ethoxybenzaldehyde 95%

- 3-Allyl-5-ethoxy-4-hydroxybenzaldehyde 95%

- 3-Allyl-4-ethoxy-5-methoxybenzaldehyde 95%

- 3-Allyl-5-ethoxy-4 methoxybenzaldehyde

- 3-Allyl-5-ethoxy-4 propoxybenzaldehyde

- 3-Allyl-5-ethoxy-4-(2-propyn-1-yloxy) benzaldehyde

- 2-Allyl-3-hydroxybenzaldehyde 95%

- 3-Allyl-4-hydroxybenzaldehyde 95%

- 2-Allyl-3-hydroxy-4-methoxybenzaldehyde 95%

- 3-Allyl-4-hydroxy-5-methoxybenzaldehyde 95%

- 5-Allyl-2-hydroxy-3-methoxybenzaldehyde 95%

- 1-Allyl-1h-indole-3-carbaldehyde 95%

- 3-Allyl-4-isopropoxybenzaldehyde 95%

- 3-Allyl-4-isopropoxy-5-methoxybenzaldehyde 95%

- 3-Allyl-4-methoxybenzaldehyde 95%

- 3-Allyl-5-methoxy-4-propoxybenzaldehyde 95%

- 1-Allyl-3-methyl-1h-pyrazole-4-carbaldehyde 95%

- 1-Allyl-5-methyl-1h-pyrazole-4 carbaldehyde

- 2-Allyloxybenzaldehyde 98%

- 3-(Allyloxy)benzaldehyde 95%

- 4-Allyloxybenzaldehyde 95%

- 2-(Allyloxy)-5-bromobenzaldehyde 95%

- 4-(Allyloxy)-3-bromobenzaldehyde 95%

- 4-(Allyloxy)-3-bromo-5-methoxybenzaldehyde 95%

- Fluorides

- 2-Amino-3,4-difluorobenzoic acid 98%

- 5-(benzyloxy)-1-chloro-2-fluoro-3- (trifluoromethyl)benzene

- 2-(Benzyloxy)-1-bromo-5-fluoro -3-nitrobenzene

- 2-Amino-4-(trifluoromethoxy) phenol

- 2-Benzyloxy- 4-fluoroaniline

- 1-[(Ammoniooxy)methyl]-4-fluorobenzene chloride

- 3-Amino-6-fluoropicoline.... 98%

- Benzyl ((4,4-difluoropiperidin-3-yl)methyl)carbamate hydrochloride

- Benzyl 3-fluoro-4-oxopiperidine-1-carboxylate

- Benzyl n-[(3s,4r)-3-fluoropiperidin-4-yl]carbamate hydrochloride

- 5-Amino-2,2-difluorobenzodioxole 97%

- 2-Amino-4'-fluorobenzophenone 97%

- Benzyl(ethyl)dimethylammonium bis(trifluoromethanesulfonyl)imide

- 2-Acetoxy-2', 4'-difluoroacetophenone

- 4-Benzyloxy-3,5-difluorophenylboronic acid

- 4-(Allyloxy) -2-fluorobenzonitrile 95%

- 1-Benzyloxy-4-(difluoromethyl) benzene

- 2H-1,4-Benzoxazin-3(4h)-one, 6,7-difluoro

- N-(1H-1,2,3-Benzotriazol-1-ylmethyl) -4-fluoroaniline

- (2R,3R,4R-3-Benzoyloxy-4-fluoro-4-methyl-5-oxotetrahydrofuran-2-yl)methyl benzoate

- 2-Amino-5-(trifluoromethyl) benzamide

- 3-Amino-4-fluorobenzotrifluoride 98%

- 3-(Benzyloxy)-5-fluorobenzoic acid

- Benzyl 3-fluoropropanoate

- 2-Benzyloxy-4- bromobenzotrifluoride

- Benzyl N-[4-(4-cyano-3-fluorophenyl)phenyl]carbamate

- 5-Acetyl-2, 2-difluoro-1,3-benzodioxole

- 2-Amino-4-(4-fluorophenyl)thiazole 98%

- 5-Amino-3-(3-fluorophenyl)-1-methylpyrazole ....95%

- (S)-3-Amino-3-(4-trifluoromethylphenyl)propionic acid

- 4-Amino-3-(trifluoromethoxy)phenylboronic acid, pinacol ester

- 3-(benzyloxy)-1-chloro-2,4-difluoro-5- methylbenzene

- 4-Amino-3-(trifluoromethoxy) benzonitrile

- 2-Amino-6-(trifluoromethyl) benzonitrile

- 5-Amino-8- trifluoromethoxyquinoline

- 2-Amino-5-(trifluoromethyl)benzoic acid

- 4-Amino-2-(trifluoromethyl)benzoic acid

- 4-amino-3-(trifluoromethyl) benzonitrile

- 2-Amino-4-(trifluoromethyl)phenol hydrochloride

- 2-Amino-1-(4-(trifluoromethyl)phenyl)ethanone hydrochloride

- 5-Amino-3-(trifluoromethyl) pyridin-2-ol

- 2-Amino-4-[(trifluoromethyl)sulfonyl] phenylamine

- 1-[(Ammoniooxy)methyl]-3-(trifluoromethyl)benzene chloride

- (3Ar,4r,5r,6as)-4- ((e)-3,3-difluoro-4-phenoxybut-1-en-1-yl)-5-hydroxyhexahydro-2h-cyclopenta[b]furan-2-one

- 3-Amino-3-(3-trifluoromethylphenyl)propanoic acid

- 2-(benzyloxy)-1-chloro-3,5- difluorobenzene

- 2-Amino-4- trifluoromethyloxazole

- Ammonium perfluoro(2-methyl-3-oxahexanoate)

- 7-[(4aS,7aS)-Octahydro-1H-pyrrolo[3,4-b]pyridin-6-yl]-1-cyclopropyl-6-fluoro-8-methoxy-4-oxo-1,4-dihydroquinoline-3-carboxylic acid hydrochloride

- Acetic acid 3-fluoro-4-methyl-phenyl ester

- 2-(Benzyloxy)-1-bromo-3,5- difluorobenzene

- 3-(Benzyloxy)-2,6-difluorophenylboronic acid

- 2-(benzyloxy)-4-chloro-1- (trifluoromethyl)benzene

- 2-Amino-5-fluorothiazole hydrochloride 97%

- 2-Amino-3-nitro-5- fluoropyridine

- (1-Benzyl-4-fluoropiperidin-3-yl) methanol

- 1-Benzyl-3,3-difluoro-4, 4-piperidinediol

- Benzyl chlorofluoroacetate

- 3-(Benzyloxy)-6-bromo-2- fluorophenol

- 3-Amino-4-(trifluoromethoxy) benzonitrile

- 2-Amino-6-(trifluoromethyl) pyridine

- 3-Amino-1,1, 1-trifluoropropan-2-ol

- 3-Amino-4-(trifluoromethyl)phenylboronic acid

- 2-Amino-5-fluoro-4-methylphenylboronic acid, pinacol ester 97%

- 1-(Azetidin-3-yl)-3-fluoroazetidine oxalate

- 1-Benzoyl-3-[4-(trifluoromethyl) phenyl]thiourea

- Benzyl [2-(3,5-bis(trifluoromethyl)phenyl)-1-methyl-2-oxo-ethyl]carbamate

- : 3-(Benzyloxycarbonylamino)-4-fluorophenylboronic acid, pinacol ester

- 3-Amino-5-(trifluoromethyl) pyridin-2(1H)-one

- 3-(Benzylcarbamoyl)-4-fluorophenylboronic acid

- (1-Benzyl-4,4-difluoropiperidin-3-yl) methanol

- 2-Amino-2'-fluoro-5-nitrobenzophenone 98%

- 5-(4-Aminophenyl)-2-fluorobenzoic acid

- 1-Benzoyl-3- (2,3-difluorophenyl)thiourea

- 2-Amino-3-methoxy-4-fluorobenzoic acid 98%

- 6-Amino-3-(4-fluorophenyl)picolinic acid ....98%

- Benzyl ((3-fluoroazepan-3-yl)methyl)carbamate

- 1-(Azetidin-3-ylcarbonyl)azepane trifluoroacetate

- Benzoic acid pentafluorophenyl ester

- 3-Amino-3-(2-fluorophenyl)propanoic acid 98%

- 2-Aminomethy-4-(4-fluorobenzyl) morpholine

- 1-Benzyl-4,4- difluoropiperidine

- 4-Amino-2- trifluoromethylpyridine

- 3-Amino-5-fluoro-1-methylindazole 98%

- 3-Amino-2-hydroxy-5-(trifluoromethyl)pyridine 98%

- 2-Amino-3- trifluoromethylbenzonitrile

- 3-Amino-5-bromo-2-fluorobenzoic acid 96%

- 1-Benzhydryl-3-(trifluoromethyl) azetidin-3-ol

- 3-Amino-5-fluorobenzotrifluoride 98%

- Benzyl N-[1-(4-fluorophenyl)cyclobutyl]carbamate

- Benzyl N-[2-(4,4-difluoropiperidin-1-yl)-2-oxoethyl]carbamate

- N-benzyl-3-chloro-5- fluorobenzamide

- 4-Amino-3-fluorobenzonitrile 98%

- 1-(2-Aminophenyl) -2,2,2-trifluoroethan-1-one

- Benzyl 2-fluoro-6-nitrobenzoate

- 2-Amino-5-fluorobenzaldehyde 96%

- 2-Amino-4-fluoro-5-methoxybenzoic acid 98%

- 2-Amino-4-fluoropyridine 98%

- 3-Amino-2-methyl benzotrifluoride

- 2-Amino-3-fluoropyridine 98%

- 4-Acetamido-3-fluorophenylboronic acid, pinacol ester

- 1-Acetyl -2-bromo-4-fluorobenzene

- 2-Acetamido-4-(trifluoromethyl)phenylboronic acid, pinacol ester

- 6-Acetamido-2, 3-difluoroanisole

- 2-Amino-4-bromo-6-fluorobenzothiazole 95%

- N-Benzyl 3-bromo-5-trifluoromethylbenzenesulfonamide

- 4-(Azetidin-3-yl)-2,2-dimethylmorpholine ditrifluoroacetate

- 1-(Azetidin-3-yl) -4,4-difluoropiperidine

- 1-(Azetidin-3-yl) -3-fluoroazetidine

- 1-(benzyloxy)-3,5-dichloro- 2-fluorobenzene

- 1-(benzyloxy)-3-chloro-5- (trifluoromethoxy)benzene

- 1-(benzyloxy)-3, 5-difluorobenzene

- Benzyl N-(3-bromo-2-fluorophenyl)carbamate

- 3-Amino-5-bromo-2-fluoropyridine 98%

- 5-Fluorocytosine 98%

- 2-Acetamido-5-fluorophenylboronic acid, pinacol ester

- 1-Benzyloxy-2-chloro-4- fluorobenzene

- Azido-peg4-pfp ester

- 2-Amino-4-fluorobenzo[d]thiazole 96%

- 4-Amino-2-fluoro-5-methylbenzonitrile 98%

- (3As,4r,6ar) -6-((benzyloxy)methyl)-5-fluoro-2,2-dimethyl-4,6a-dihydro-3ah-cyclopenta[d][1,3]dioxol-4-ol

- (4R,12As)-n- (2,4-difluorobenzyl)-7-methoxy-4-methyl-6,8-dioxo-3,4,6,8,12,12a-hexahydro-2h-[1,3]oxazino[3,2-d]pyrido[1,2-a]pyrazine-9-carboxamide

- 3-Amino-2-fluoro-6-methylpyridine 98%

- Azetidin-1-yl(azetidin-3-yl)methanone trifluoroacetate

- 4-Amino-2-fluorophenylboronic acid pinacol ester...97%

- 2-Amino-3- trifluoromethylpyridine

- (+/-)-Alpha-methoxy-alpha-trifluoromethylphenylacetic acid 98%

- 3-Azetidineacetic acid trifluoroacetate

- Benzyl (3-fluoro-4-morpholinophenyl)carbamate

- 4-Amino-2,5-difluorobenzonitrile 97%

- 2-(Azetidine-1-carbonyl) -4-fluoroaniline

- [(3S,4R)-1-Benzyl-4-(3-fluorophenyl)pyrrolidin-3-yl] methanol

- 2-Amino-4-trifluoromethylphenyl disulfide

- 2-Amino-4-fluorobenzaldehyde 96%

- 5-Amino-2- trifluoromethylpyridine

- 2-Amino-3-fluorobutyric acid 95%

- N-(4-Acetylphenyl)-2,2,2-trifluoroacetamide 95%

- 4- Benzyloxybenzotrifluoride

- N-(4-(Benzyloxy)benzylidene) -4-fluoroaniline

- L-Asparagine 7-amido-4-methylcoumarin trifluoroacetate

- (3R)-3-Amino-1-[3-(trifluoromethyl) -5H,6H,7H,8H-[1,2,4]triazolo[4,3-a]pyrazin-7-yl]-4-(2,4,5-trifluorophenyl)butan-1-one

- 4-Azidosulfonyl-benzoic acid pentafluorophenyl ester

- 2-[4-Amino-3-(trifluoromethyl) phenyl]acetonitrile

- N-(2-Benzoyl-4-chlorophenyl) -3,4-difluorobenzamide

- (S)-1-(Azetidin-3-yl)-3-fluoropyrrolidine dihydrochloride

- 4-(Benzyloxy)-3-chloro-5-fluorophenylboronic acid

- 5-Amino-2-fluorobenzamide 98%

- 5-Amino-2-fluoropyridine 97%

- N-Benzyl-3- fluorobenzamide

- 3-Amino-4-fluorobenzoic acid hydrochloride 98%

- 1-Benzoyl-3-(3-fluorophenyl) thiourea

- 1-Benzyl-3,3-difluoro-4- phenylpiperidin-4-ol

- 4-(benzyloxy)-2-chloro-1- fluorobenzene

- 1-(4-Amino-3-fluorophenyl)ethanone 98%

- 4-Amino-2-fluoro-5-methylbenzenesulfonamide F310

- Benzyl N-(5-bromo-2,3-difluorophenyl)carbamate

- 3-(Benzylcarbamoyl)-5-fluorophenylboronic acid

- 4-Acetyl-2,2-difluoro-1, 3-benzodioxole

- Benzyl [(1r)-2-(3,5-bis(trifluoromethyl)phenyl)-1-methyl-2-oxo-ethyl]carbamate

- 4-Amino-2-fluoropyridine 98%

- 2-Amino-5-fluoro-4-picoline 95%

- N-Benzyl-4- fluorobenzenesulfonamide

- 2-(Benzyloxy)- 5-fluorobenzonitrile

- 6-Amino-2-bromo-3-fluorophenol 97%

- (4R,12As)-n-(2,4-difluorobenzyl) -7-methoxy-4-methyl-6,8-dioxo-3,4,6,8,12,12a-hexahydro-2h-[1,3]oxazino[3,2-d]pyrido[1,2-a]pyrazine-9-carboxamide

- Benzyl N-(3,3-difluoro-1-methylcyclobutyl)carbamate

- Benzyl N-[2-(4-fluorophenyl)propan-2-yl]carbamate

- 4-Acetamido-3-fluorobenzoic acid

- 2-Aminomethyl-4-fluorophenylboronic acid, pinacol ester

- 5-Amino-2-fluorobenzyl alcohol 96%

- 2-Amino-5-fluorophenol 95%

- 1-(benzyloxy)-2-chloro-3 -fluorobenzene

- 1-(benzyloxy)-3-chloro-2,4- difluorobenzene

- 5-Benzyloxy- 2-fluoroaniline

- Benzoyl trifluoromethanesulfonate

- Benzyl ((4-fluoroazepan-4-yl)methyl)carbamate hydrochloride

- 3-Amino-6-fluoro-1-methylindazole 98%

- N-Benzyl-2-fluoroaniline hydrochloride

- (S)-2-(2-((S)-2-Acetamido-4-methylpentanamido)acetamido) -n-(4-methyl-2-oxo-2h-chromen-7-yl)-6-(2,2,2-trifluoroacetamido)hexanamide

- 2-Acetamido -1-nitro-3,5,6-trifluorobenzene

- Benzoic acid, 3,4,5-trifluoro-, 1,1-dimethylethyl ester

- 2-Aminomethyl-4-fluorophenylboronic acid hydrochloride

- 1-Benzenesulfonyl-5-fluoro-1h-pyrrolo [2,3-b]pyridine

- 2'-Amino-5'-chloro-2,2,2-trifluoroacetophenone 98%

- 3-Benzyloxy-2-chloro-6-fluorophenylboronic acid

- 2H-1,4-Benzoxazine, 7-fluoro-3,4-dihydro-3-methyl-

- 4-(Benzyloxy)-3-fluoroaniline hydrochloride

- 2-Amino-5-chlorobenzotrifluoride 98%

- 2-(Benzyloxy)-5-chloro-3- fluoropyridine

- 2-Amino-3-fluorobenzoic acid 98%

- N6-Benzoyl-2'-fluoro-2'- deoxyadenosine

- 2-Benzyloxy- 6-fluorobenzonitrile

- Benzoyl-1,1,1- trifluoroacetone

- 1-(Azetidin-3-yl)-3-methylazetidin-3-ol di-trifluoroacetate

- 2-Aminohexafluoropropan-2-ol 95%

- 4-Amino-2-fluorobenzonitrile 98%

- 2-Amino-6-fluorobenzonitrile 98%

- N4-Benzoyl-2'-fluoro-2'- deoxycytidine

- 1-Benzoyl-3-(2,4-difluorophenyl) thiourea

- 4-Amino-5-fluoro-1-[(2R,5S)-2-(hydroxymethyl)-1,3-oxathiolan-5-yl]-1,2-dihydropyrimidin-2-one 98%

- 2-Amino-5- nitrobenzotrifluoride

- benzyl N-(3-chloro-2-fluorophenyl)carbamate

- 1-Acetamido-3, 5-difluorobenzene

- : {[(2R,3S,4S,5R)-5-(6-Amino-2-fluoro-9H-purin-9-yl)-3,4-dihydroxyoxolan-2-yl]methoxy}phosphonic acid 97%

- 1-(benzyloxy)-5-chloro-2, 4-difluorobenzene

- 2-Benzyloxy-1, 3-difluorobenzene

- 4-(6-Aminopyridin-3-yl)-N-ethyl -2-fluorobenzamide

- 5-Aminomethyl-4-2luorophenylboronic acid, pinacol ester

- 5-Amino-2-fluorophenylacetic acid 98%

- 4-(3-Aminophenyl)-N-ethyl-2- fluorobenzamide

- benzyl N-(3-chloro-5-fluorophenyl)carbamate

- Benzyl N-(4-bromo-2-fluorophenyl)carbamate

- 2-(Benzyloxy)- 5-fluorobenzamide

- (R)-1-(Azetidin-3-yl) -3-fluoropiperidine

- 1-[2-(Benzyloxy)ethoxy]-3-bromo- 5-fluorobenzene

- 5-Amino-4-cyano-1-(4-fluorophenyl)-3-methylpyrazole 97%

- 1-Benzyl-3,3-difluoropiperidin -4-one

- 2-Amino-3-chloro-5-trifluoromethylpyridine 98%

- 4-Amino-3-(trifluoromethoxy)benzoic acid

- 4-(benzyloxy)-2, 3-difluorophenol

- (1-Benzyl-4-fluoropiperidin-3-yl)methyl acetate

- 4-(1,3-Benzodioxol-5-yl)-6-(trifluoromethyl) pyrimidine-2-thiol

- 2-Amino-4,4,4-trifluoro-n-butyric acid hydrochloride

- 4-(Benzyloxy)- 2-fluoroaniline

- 2-Acetamido-4-fluorobenzoic acid

- 2-Amino-5- trifluoromethylbenzonitrile

- 4-Amino-5-chloro-2-ethoxy-N-({4-[(4-fluorophenyl)methyl]morpholin-2-yl}methyl)benzamide 98%

- 4-Amino-2-fluorobenzotrifluoride 97%

- 2-Amino-5-bromo-3-trifluoromethylpyridine 98%

- 2-(Benzyloxy)-3,5-difluorophenylboronic acid

- 2-Amino-6-fluorobenzoic acid 98%

- 5-Amino-2-methoxy-3-(trifluoromethyl) pyridine

- 3-Amino-4-fluorophenol 97%

- 2-Amino-5-fluoro-3-iodopyridine 95%

- 3-(Benzyloxy)-6-bromo-2- fluoroanisole

- 1-Benzyl-3-bromo-5-(trifluoromethyl) pyridin-2(1H)-one

- Benzyl (5,5-difluoropiperidin-3-yl)carbamate hydrochloride

- 1-(Azetidin-3-yl)-4-fluoropiperidine dihydrochloride

- ((2R,3R,5R)-3-(Benzoyloxy)-4,4-difluoro-5-((methylsulfonyl)oxy)tetrahydrofuran-2-yl)methyl benzoate

- 1-Acetamido-4-bromo-2- (trifluoromethoxy)benzene

- 1-Benzyl-5-bromo-6- fluorobenzimidazole

- 1-(Benzyloxy)-2,4-dibromo-5- fluorobenzene

- 4-Acetamido -3-bromobenzotrifluoride

- 2-Amino-5-(4-fluorophenyl)isonicotinic acid 97%

- 1-(Benzyloxy)- 4-fluorobenzene

- 1-(benzyloxy)-2-chloro-5-fluoro- 4-methylbenzene

- 2-(Benzofuran-2-yl) -4-fluorobenzonitrile

- 2-(benzyloxy)-1,4-dichloro- 3-fluorobenzene

- 2-Benzoxazol-2-yl-1-(3-trifluoromethylphenyl) ethanol

- [3-Acetyl-5-(4-fluorophenyl)-2-methyl-1h-pyrrol-1-yl]acetic acid 95%

- 2-Azaspiro[3.3]heptan-6-ol trifluoroacetate

- 3-Amino-3-(3-fluorophenyl)propanoic acid 97%

- 5-Amino-2-fluorobenzonitrile 97%

- Benzyl N-(4-chloro-2-fluorophenyl)carbamate

- (2S,3R,4S,5S,6R)-2-(3-(Benzo[b]thiophen-2-ylmethyl)-4-fluorophenyl) -6-(hydroxymethyl)-2-methoxytetrahydro-2h-pyran-3,4,5-triol

- 2-Amino-4-fluorobenzonitrile 98%

- 3-Amino-2-(2-fluorophenoxy)pyridine 95%

- Benzyl 5-fluoropiperidin-3-ylcarbamate hydrochloride

- 2-(benzyloxy)-1-chloro-4- fluorobenzene

- N-Benzyl-4-bromo-5-fluoro-2- nitroaniline

- 2-(N-Benzylamino) -5-chloro-3-fluoropyridine

- [2-Amino-1-(4-fluorophenyl)ethyl]dimethylamine 96%

- 4-Amino-2-fluoro-5-methoxybenzonitrile 98%

- 2-Amino-5-fluoropyridine 97%

- 6-Amino-3-Bromo-2-trifluoromethylpyridine 98%

- N-Acetyl-3-(2,5-difluorophenyl) -d-alanine

- Benzyl (2-(4-((4-fluorobenzyl)carbamoyl)-5-hydroxy-6-oxo-1,6-dihydropyrimidin-2-yl)propan-2-yl)carbamate

- 1-(Benzyloxy)-4-bromo-2-(trifluoromethyl) benzene

- 2-(Benzyloxy)-1-chloro-3 -fluorobenzene

- 4-Amino-5-bromo-2-(trifluoromethyl)benzonitrile 97%

- 2-Amino-3-fluorobenzonitrile 98%

- 2-Amino-5-methoxybenzotrifluoride 98%

- 3-Amino-5-chlorobenzotrifluoride 98%

- Amyltriethyl ammonium

- 3-(4-Benzyl-3-oxo-7-trifluoromethyl-3,4-dihydro-quinoxalin-2-yl)-propionic acid

- 1-(Azetidin-3-yl)-3,3-difluoropyrrolidine dihydrochloride

- 4-Acetoxy-2,3,5,6-tetrafluorobenzoic acid

- 1-Acetoxy -2-fluorobenzene

- 3-Amino-4-fluorophenylboronic acid, pinacol ester 96%

- 3-Amino-2-fluorobenzonitrile 97%

- 2-Acetamido-5-fluorobenzoic acid

- 6-Amino-2-fluoropyridine-3-boronic acid pinacol ester 95%

- 3-(1H-Benzoimidazol-2-yl) -1,1,1-trifluoro-propan-2-one

- 3-(benzyloxy)-1-chloro-2,4-difluoro- 5-methylbenzene

- Benzyl N-[3,5-bis(trifluoromethyl)phenyl]carbamate

- benzyl N-(5-chloro-2-fluorophenyl)carbamate

- Acetamide, n-[4-[2,2,2-trifluoro-1-hydroxy-1-(trifluoromethyl)ethyl]phenyl]-

- 6-Benzyl-2,4-dichloro-8,8-difluoro-5,6,7,8-tetrahydropyrido[4,3-d]pyrimidine hydrochloride

- 2-Acetamido -3-bromo-5-fluoropyridine

- (2R,3R,4S,5R)-2-[(Benzoyloxy)methyl]-5-(2,4-dioxo-1,2,3,4-tetrahydropyrimidin-1-yl)-4-fluorooxolan-3-yl benzoate

- Benzyl (2,4-difluorophenyl)carbamate

- Benzenepropanoic acid, 2,3,6-trifluoro-

- 3-Benzyloxy-4-chloro-2-fluorophenylboronic acid

- 2-Amino-5-chloro-3-fluoropyridine 98%

- 2-(benzyloxy)-5-chloro-1,3- difluorobenzene

- 7-[(4aS,7aS) -Octahydro-1H-pyrrolo[3,4-b]pyridin-6-yl]-1-cyclopropyl-6-fluoro-8-methoxy-4-oxo-1,4-dihydroquinoline-3-carboxylic acid hydrochloride

- (4-Amino-2-fluorophenyl)acetic acid 98%

- 3-[3-Acetyl-5-(4-fluorophenyl)-2-methyl-1h-pyrrol-1-yl]propanoic acid 95%

- 4- Acetylbenzotrifluoride

- 5-(Benzyloxy)-2 -bromobenzotrifluoride

- 2-Acetamido -5-fluorotoluene

- 2-Amino-5-fluoropyrimidine 98%

- 2-Amino-5-fluorobenzonitrile 97%

- 2-Amino-5-fluoronicotinic acid 97%

- 2-Amino-4-trifluoropyrimidine-5-boronic acid pinacol ester

- Benzyl N-[1-(2-fluorophenyl)cyclopropyl]carbamate

- 2-Amino-3-bromo-5-fluorobenzoic acid 96%

- 1-(4-Azepan-1-yl-3-fluorophenyl) ethanone

- 2-Benzyloxy-1-bromo-4- fluorobenzene

- 3-Amino-4-methyl-n-[3-(trifluoromethyl) phenyl]benzenesulfonamide

- 5-Amino-3-(2-fluorophenyl)-1-methylpyrazole .....96%

- 3-Amino-2-fluoropyridine 97%

- 3-Amino-4-fluorobenzoic acid 98%

- 2-Amino-4-fluorobenzamide 98%

- 1-Benzoyl-3-(2,5-difluorophenyl) thiourea

- 3-(2-Amino-5-fluoropyridin-3-yl)prop-2-yn-1-ol 95%

- N-Benzyl-2-chloro-n-(4-fluorophenyl) acetamide

- [1-(Azetidin-3-yl)-4-piperidyl]methanol di trifluoro acetic acid salt

- Benzyl (3,3-difluoro-2-hydroxypropyl)carbamate

- 5-Amino-3-fluorobenzonitrile 97%

- 4-Amino-2-ethoxy-5-fluorobenzonitrile 96%

- N-(2-Amino-3-fluorophenyl)methanesulfonamide 96%

- Benzoic acid, 4-[(1,2,2-trifluoroethenyl)oxy]-

- 4-Amino-5-(2-fluorophenyl)-4h-1,2,4-triazole-3-thiol 95%

- 4-Amino-2-fluorobenzoic acid 98%

- 2-Aminomethyl-3-chlorophenylboronic acid, pinacol ester

- 3-Amino-4-mercaptobenzotrifluoride hydrochloride 95%

- Azetidin-3-yl(3-fluorophenyl) methanone

- Benzyl 3,3-difluorocyclobutylcarbamate

- Ammonium hexafluorozirconate

- 2-(Benzyloxy)-3-bromo-5- fluoroaniline

- Benzoyl -1,1,1-trifluoroacetone

- 3-Amino-3-(2-fluorophenyl)propan-1-ol hydrochloride 98%

- 4-Aminophenylsulfur pentafluoride

- 2-Amino-2-(4-fluoro-phenyl)-propionic acid 95%

- 2-Amino-3,5-difluoropyridine 97%

- 4-Acetamido-2-fluoro-5-methylbenzenesulfonyl chloride

- 2-(Benzylaminomethyl) -4-bromo-1-fluorobenzene

- 2-Amino-5-trifluoromethyl -1,3,4-thiadiazole

- 3-Amino-5-methyl benzotrifluoride

- 1-(Benzyloxy)-3-bromo-5- fluorobenzene

- benzyl N-(4-chloro-3-fluorophenyl)carbamate

- N-(4-Acetylphenyl)-2,2,3,3,4,4,4- heptafluorobutanamide 95%

- 2-Amino-4,6-difluoropyrimidine 96%

- Benzyl (5-fluoroazepan-4-yl)carbamate hydrochloride

- 2-Amino-6-(trifluoromethoxy) phenol

- 4-(benzyloxy)-1-chloro-2-(trifluoromethyl) benzene

- 5-Amino-3-(2-fluorophenyl)-1-methylpyrazole ...96%

- 1-(Azetidin-3-yl)pyrrolidin-2-one trifluoro acetate

- ((3Ar,5r,6s,6ar)-2,2-dimethyl-6-(((trifluoromethyl)sulfonyl)oxy)tetrahydrofuro[2,3-d][1,3]dioxol-5-yl)methyl 4-methylbenzoate

- 1-(benzyloxy)-2,4-difluoro- 5-nitrobenzene

- (3Ar,4r,5r,6as) -4-((e)-3,3-difluoro-4-phenoxybut-1-en-1-yl)-5-hydroxyhexahydro-2h-cyclopenta[b]furan-2-one

- 4-(Benzyloxy)-3-bromo-5- fluoroaniline

- 2-Amino-4'-fluoroacetophenone hydrochloride 97%

- 3-Amino-5-trifluoromethylphenylboronic acid, pinacol ester

- 4-Amino-2-fluoro-N-methylbenzamide 98%

- Benzyl[(5-fluoropyridin-2-yl) methyl]amine

- 2-Amino-4-(trifluoromethyl)pyridine-5-boronic acid pinacol ester

- (2R)-2-Amino-3-[4-(trifluoromethoxy)phenyl]propanoic acid

- 4-Benzyloxy-2-fluoroaniline hydrochloride

- 3-Amino-4- (trifluoromethyl)pyridine

- 5-Amino-2-fluorobenzoic acid 95%

- 1-(benzyloxy)-2,3-dichloro- 4-fluorobenzene

- [3-(Benzyloxy)-2,4-difluoro-5-methylphenyl]boronic acid

- [4-Amino-2-(trifluoromethyl)phenyl] (4-methyl-1-piperazinyl)methanone

- 5-Amino-8-fluoroquinoline 98%

- 1-Benzyl-5-bromo-6-fluoro-2-methyl-1, 3-benzodiazole

- 5-Amino-2-fluoro-4-hydroxybenzoic acid 95%

- 4-Amino-3-(trifluoromethyl)benzoic acid

- 2-Amino-6-fluorobenzothiazole 98%

- 4-(Benzyloxy)- 2-fluorobenzonitrile

- 5-Amino-2-fluoro-3-picoline 98%

- 2-(benzyloxy)-1-chloro-4 -fluorobenzene

- 2-Acetamido -6-trifluoromethylpyridine

- 1-(1,3-Benzodioxol-5-yl) -4,4,4-trifluorobutane-1,3-dione

- 1-(Azetidin-3-ylcarbonyl)-4-methylpiperazine bis(trifluoroacetate)

- 5-(Benzyloxy)-2- bromobenzotrifluoride

- 4-(Aminomethyl)-3-(trifluoromethyl) aniline

- 2-Amino-4-fluorobenzoic acid 98%

- 2-Amino-4,5,6- trifluorobenzothiazole

- 4-Amino-3-fluorophenol 97%

- 2-Amino-5-(4-fluorobenzylthio)-1,3,4-thiadiazole 95%

- Benzyl 2-(benzyloxy)-4-fluorobenzoate

- 2-Amino-5-[4-fluoro-3-(trifluoromethyl)phenyl]pyridine 98%

- Benzoic acid, 3-(3-fluoropropoxy)-

- 5-Amino-2-methyl benzotrifluoride

- (3-Amino-2-fluorophenyl)methanol.... 97%

- 3-Amino-2-(methylamino)-5-(trifluoromethyl) pyridine

- 1-(Azetidin-3-yl)-4,4-difluoropiperidine ditrifluoroacetic acid salt

- 2-Aminomethyl-5-fluorophenylboronic acid hydrochloride

- 2-Acetamido-4,4,4-trifluorobutanoic acid

- N-Benzyl 2-bromo-5-trifluoromethoxybenzenesulfonamide

- Benzeneacetamide, 4-fluoro-n-[4-(5-oxazolyl)phenyl]-

- 4-(4-Aminophenyl)-N-ethyl-2- fluorobenzamide

- (R)-3-Amino-3-(3-trifluoromethylphenyl)propanoic acid

- (3S,11Ar)-n-(2,4-difluorobenzyl) -6-methoxy-3-methyl-5,7-dioxo-2,3,5,7,11,11a-hexahydrooxazolo[3,2-d]pyrido[1,2-a]pyrazine-8-carboxamide

- Benzyl N-[2-(3-fluoropyridin-4-yl)ethyl]carbamate

- 2-Amino-4-(trifluoromethyl)thiazole-5-carboxylic acid

- Ammonium trifluoroacetate

- 2-Amino-3-(trifluoromethoxy)benzoic acid

- 1-({[(Benzyloxy)carbonyl]amino}amino)- 2,2,2-trifluoroethanone

- 3-Amino-7-fluoro-1-methylindazole 96%

- (3R)-1-(3-Azetidinyl)-3-fluoro-pyrrolidine dihydrochloride

- 2-Amino-6-fluorobenzaldehyde 98%

- 3-Amino-n-(3-trifluoromethyl-phenyl) -benzenesulfonamide

- N-Benzyl-5-chloro-2- fluorobenzamide

- 4-(Azetidin-3-ylcarbonyl)morpholine trifluoroacetate

- Benzonitrile,4-(methylsulfonyl) -3-(trifluoromethyl)-

- 4-Amino-n-[4-(trifluoromethyl) phenyl]benzenesulfonamide

- 4-Amino-2,3,5,6- tetrafluoropyridine

- [2-Amino-1-(2-fluorophenyl)ethyl]dimethylamine 95%

- 3-Amino-5-fluoropyridin-2-ol 96%

- 4-(Benzyloxy)-2,3-difluorophenylboronic acid

- 1-Benzyl-3,3-difluoropiperidin-4-one oxime

- 5-Amino-3-[3-(trifluoromethyl)phenyl] isoxazole

- 4-(1H-Benzimidazol-2-yl)-1-[3-(trifluoromethyl)phenyl] pyrrolidin-2-one

- 2-Amino-5-fluorobenzotrifluoride 98%

- 3-(benzyloxy)-1-bromo-2,4-difluoro-5 -methylbenzene

- 2-Amino-5-(3,5-difluorophenyl)pyridine 98%

- 1-(benzyloxy)-3-chloro-5- fluorobenzene

- 2-Amino-4-bromo-5-fluorophenol 96%

- 2-Amino-6-fluorobenzamide 98%

- 1-(benzyloxy)-4-chloro-2 -fluorobenzene

- 2-Amino-3-(trifluoromethyl)benzoic acid

- 3-Amino-n-(2-fluoro-phenyl)-benzenesulfonamide 95%

- 4-(Benzyloxy)-1-chloro- 2-fluorobenzene

- 2-Amino-5-fluoro-6-methylpyridine 98%

- Aluminum trifluoromethanesulfonate 95%

- (R)-2-Acetamido-2-(2-fluorophenyl)propanoic acid

- 1,3-Benzodioxole, 4-chloro-2,2-difluoro-

- 2-(4-Aminophenyl) -6-fluorobenzothiazole

- 4-Amino-3-fluorobenzoic acid 98%

- 4-Amino-2,6-difluoropyridine 97%

- 5-Amino-2-fluoro-4-picoline 95%

- 3-Amino-5-(trifluoromethyl) benzonitrile

- 5-Amino-2-pyrrolidin -1-yl-n-(3-trifluoromethyl-phenyl)-benzenesulfonamide

- 2-Amino-5-(4-trifluoromethoxyphenyl) pyridine

- Azetidin-3-yl acetate 2,2,2-trifluoroacetate

- 1-(Azetidin-3-yl)-3-fluoropyrrolidine dihydrochloride

- (S)-3-Amino-4-(2-trifluoromethylphenyl)butanoic acid hydrochloride

- 2-Amino-5-(trifluoromethoxy) benzonitrile

- 1-Benzyl-5-bromo-6- fluorobenzotriazole

- 2-Amino-3-fluorophenol hydrochloride....98%

- 4-Amino-3- nitrobenzotrifluoride

- 2-Amino-4-(trifluoromethyl) pyrimidine

- 2-Amino-2-(2-fluorophenyl)ethanol 95%

- 4-Amino-2-(trifluoromethyl) benzonitrile

- 4-Amino-2-(trifluoromethyl) phenol

- 3-Amino-n-(2,2,2-trifluoroethyl) benzamide

- 3-Amino-2-fluorobenzotrifluoride 98%

- 2-Amino-4-chlorobenzotrifluoride 97%

- 3-(Benzyloxycarbonylamino)-4-fluorophenylboronic acid, pinacol ester

- 4-(Benzyloxy)-3,5-difluorobenzoic acid

- 3- Benzyloxybenzaldehyde

- 3-Amino-3-(3-fluorophenyl)propanoic acid...97%

- 5-Amino-6-Chloro-2,2-difluorobenzodioxole 97%

- 4-(6-Aminopyridin-3-yl)-2-fluorobenzoic acid

- 2-Amino-5-(4-fluoro-3-methoxyphenyl)pyridine F308

- Benzyl 1-(4-fluorophenyl)cyclopropylcarbamate

- 2-Amino-6-(trifluoromethoxy) benzo[d]thiazole

- (S)-3-Amino-3-(3-trifluoromethylphenyl)propionic acid

- 6-Benzyl-8,8-difluoro-5,6,7,8-tetrahydropyrido[4,3-d] pyrimidine-2,4-diol

- N-Acetyl-3-(2,5-difluorophenyl) -l-alanine

- 3-Acetyl-4-fluorobenzoic acid

- 4-Acetyl-3-fluorobenzoic acid

- 4-Acetyl-3-fluoro-benzoic acid benzyl ester

- 4-Acetyl-3-fluoro-benzoic acid methyl ester

- 4-Acetyl-3-fluoro-benzoic acid tert-butyl ester

- 2-Acetyl-5- fluorobenzonitrile

- N-Acetyl 5-fluoro-2-methylaniline

- N-Acetyl 2-fluoro-4-(3-hydroxy-3-methylbut-1-ynyl)aniline

- 3-Acetyl-7-fluorochromen -2-one

- 4-Acetyl-n-(4-fluorobenzyl) benzenesulfonamide

- 4-Acetyl -n-(4-fluorobenzyl)benzenesulfonamide

- 2'-Acetyl-4-fluoro-3- methylbiphenyl

- 5-Acetyl-2-fluorophenylboronic acid, pinacol ester

- 2-Acetyl-3-fluoropyridine 98%

- 3-Acetyl-2-fluoropyridine 97%

- 2-(4-Acetylphenyl)-2,2-difluoroacetic acid 95%

- N-(3-Acetylphenyl)-2-fluorobenzamide 95%

- N-(3-Acetylphenyl)-3-fluorobenzamide 95%

- N-(3-Acetylphenyl)-4-fluorobenzamide 95%

- N-(4-Acetylphenyl)-2-fluorobenzamide 95%

- N-(4-Acetylphenyl)-3-fluorobenzamide 95%

- N-(3-Acetylphenyl)-2,2,3,3,4,4,4-heptafluorobutanamide 95%

- N-(3-Acetylphenyl)-2,2,2-trifluoroacetamide 98%

- N-(4-Acetylphenyl) -2,2,2-trifluoroacetamide 95%

- 1-(4-Acetylphenyl)-2,2,2-trifluoroethanone 95%

- 6-Acetyl-2,2,3,3-tetrafluorobenzo-1,4-dioxene 95%

- S-Acetylthioglycolic acid pentafluorophenyl ester 95%

- 4-Acetyl-2-trifluoromethyl-benzoic acid 95%

- 4-Acetyl-2-trifluoromethyl-benzoic acid methyl ester 95%

- 3-Acetyl-4'-(trifluoromethyl)biphenyl 95%

- N-(1-Adamantylmethyl)-4-fluoroaniline 95%

- 1-(1-Adamantyl)-4,4,4-trifluorobutane-1,3-dione 95%

- L-Alanine-7-amido-4-methylcoumarin trifluoroacetate salt 98%

- 1-Allyl-1h-benzimidazole-2-thiol 95%

- Allyl chlorodifluoroacetate 95%

- Allyl 2-chloro-1,1,2-trifluoroethyl ether 95%

- Allyl 1h,1h-heptafluorobutyl ether 95%

- Allyl 1,1,2,3,3,3-hexafluoropropyl ether 95%

- 1-Allyl-1-methylpyrrolidinium bis(trifluoromethanesulfonyl)imide 98%

- 1-(Allyloxymethyl)-2-fluorobenzene 98%

- 2-Allyloxy-1,1,2,2-tetrafluoroethanesulfonyl fluoride 95%

- Allyl 2,2,3,3,3-pentafluoropropyl ether 97%

- Allyl 1h,1h-perfluorooctyl ether 95%

- 4-Allyl-2,3,5,6-tetrafluorobenzoic acid 90%

- Allyl 1,1,2,2-tetrafluoroethyl ether 95%

- Allyl 2,2,3,3-tetrafluoropropyl ether 95%

- N-Allyl-2,2,2-trifluoroacetamide 95%

- 2-Allyl-4-(trifluoromethoxy)aniline 95%

- 1-Allyl-2-(trifluoromethyl)benzimidazole 98%

- N-Allyl-2-(3-(trifluoromethyl)-4,5,6,7-tetrahydroindazol-1-yl)acetamide 95%

- Alpha-chloro-4-fluorobenzaldoxime 96%

- Alpha-fluorophenylacetic acid 95%

- (Alpha-fluoro)phenylacetic acid methyl ester 95%

- (R)-(+)-Alpha-methoxy-alpha-trifluoromethylphenylacetic acid 97%

- (S)-(-)-Alpha-methoxy-alpha-(trifluoromethyl)phenylacetic acid 98%

- (+)-Alpha-methoxy-alpha-(trifluoromethyl)phenylacetic anhydride 95%

- Alpha-methyl-3-(trifluoromethyl)benzyl alcohol 97%

- Alpha-methyl-m-trifluoromethylbenzyl bromide 98%

- Alpha-(p-toluenesulfonyl)-4-fluorobenzylisonitrile 98%

- (R)-Alpha-(4-trifluoromethyl-benzyl)-proline hydrochloride 95%

- (S)-Alpha-(4-trifluoromethyl-benzyl)-proline hydrochloride 95%

- Alpha-(trifluoromethyl)-gamma-butyrolactone 95%

- Alpha-(trifluoromethyl)styrene 95%

- Aluminium trifluoroacetate 95%

- 4-Aminobenzotrifluoride 98%

- 4-Amino-3',5'-bis(trifluoromethyl)biphenyl 95%

- 5-Amino-2-(4-Boc-piperazino)benzotrifluoride 98%

- 3-Amino-2-bromobenzotrifluoride 97%

- 3-Amino-4-bromobenzotrifluoride 97%

- 3-Amino-2-bromo-6-chloropyridine 97%

- 5-Amino-6-bromo-2,2-difluorobenzodioxole 98%

- 2-Amino-4-bromo-3-fluorobenzoic acid 96%

- 2-Amino-5-bromo-4-fluorobenzoic acid 95%

- 3-Amino-5-bromo-4-fluorobenzoic acid 97%

- 2-Amino-5-bromo-4-fluorophenol 97%

- 2-Amino-6-bromo-4-fluorophenol 95%

- 2-Amino-3-bromo-5-fluoropyridine 98%

- 5-Amino-3-bromo-2-fluoropyridine 97%

- 6-Amino-3-bromo-2-fluoropyridine 98%

- 4-Amino-3-bromo-5-nitrobenzotrifluoride 98%

- 2-Amino-3-Bromo-6-trifluoromethylpyridine 98%

- 3-Amino-2-bromo-6-(trifluoromethyl)pyridine 98%

- 5-Amino-2-chloro-4-fluorobenzoic acid 98%

- 5-Amino-4-chloro-2-fluorobenzoic acid 95%

- 2-Amino-5-chloro-2'-fluorobenzophenone 98%

- 2-amino-5-chloro-4-fluorophenol 95%

- 4-Amino-2-chloro-5-fluoropyrimidine 97%

- 4-Amino-6-chloro-5-fluoropyrimidine 98%

- 2-Amino-5-chloro-3-nitrobenzotrifluoride 95%

- 2-Amino-5-chloro-3-nitrobenzotrifluoride 97%

- 4-Amino-3-chloro-5-nitrobenzotrifluoride 97%

- 3-Amino-2-chloro-6-(trifluoromethyl)pyridine 98%

- 2-Amino-4-chloro-6-(trifluoromethyl)pyrimidine 97%

- : 5-Amino-4-cyano-1-(2,5-difluorophenyl)-3-methylpyrazole 96%

- 5-Amino-4-cyano-1-(2-fluorophenyl)-3-methylpyrazole 97%

- 5-Amino-4-cyano-3-methyl-1-(2,3,5,6-tetrafluorophenyl)pyrazole 98%

- 5-Amino-4,6-dibromo-2,2-difluorobenzodioxole 96%

- 2-Amino-3,5-dibromo-4-fluorobenzoic acid 98%

- 2-Amino-3,5-dibromo-6-trifluoropyridine 95%

- 2-Amino-3,5-dichlorobenzotrifluoride 97%

- 5-Amino-1-(2,6-dichloro-4-trifluoromethylphenyl)-3-cycano pyrazole 98%

- 5-Amino-1-[2,6-dichloro-4-(trifluoromethyl)phenyl]-4-(trifluoromethane)sulfinyl-1H-pyrazole-3-carbonitrile 98%

- 2-Amino-2',4'-difluoroacetophenone hydrochloride 97%

- 4-Amino-2,2-difluoro-1,3-benzodioxole 96%

- 2-Amino-3,5-difluorobenzoic acid 97%

- 2-Amino-4,5-difluorobenzoic acid 98%

- 3-Amino-2,6-difluorobenzoic acid 95%

- 4-Amino-2,5-difluorobenzoic acid 96%

- 5-Amino-2,4-difluorobenzoic acid 97%

- 2-Amino-3,4-difluorobenzonitrile 98%

- 3-Amino-2,6-difluorobenzonitrile 98%

- 4-Amino-2,6-difluorobenzonitrile 96%

- 2-Amino-4,6-difluorobenzothiazole 98%

- 4-Amino-2,5-difluorobenzotrifluoride 98%

- 4-Amino-1-[(2R,4R,5R)-3,3-difluoro-4-hydroxy-5-(hydroxymethyl)oxolan-2-yl]-1,2-dihydropyrimidin-2-one 98%

- 4-Amino-2,6-difluorophenol hydrochloride 96%

- (6-Amino-2,3-difluorophenyl)acetic acid 95%

- 5-Amino-2,3-difluorophenylboronic acid 98%

- 3-Amino-4,5-difluorophenylboronic acid, pinacol ester 96%

- 2-Amino-5-(2,3-difluorophenyl)pyridine 98%

- 4-Amino-2-fluoro-5-nitrobenzonitrile 95%

- 2-Amino-3-fluorophenol 97%

- 2-Amino-4-fluorophenol 97%

- N-(2-Amino-4-fluorophenyl)methanesulfonamide .....98%

- N-(2 Amino 4 fluorophenyl)methanesulfonamide

- N-(2-Amino-5-fluorophenyl)methanesulfonamide ....98%

- 2-Amino-3-(trifluoromethoxy) benzoic acid

- 2-Amino-6- trifluoromethylbenzothiazole

- 2-Amino-5-(trifluoromethyl) nicotinaldehyde

- 2-Amino-5- trifluoromethylpyridine

- Amino-3,3,3-trifluoropropanoic acid hydrochloride

- (4R,12As)-7-(benzyloxy) -n-(2,4-difluorobenzyl)-4-methyl-6,8-dioxo-3,4,6,8,12,12a-hexahydro-2h-[1,3]oxazino[3,2-d]pyrido[1,2-a]pyrazine-9-carboxamide

- 4-[4-Azido-2-(trifluoromethyl)benzoyl] morpholine

- (2'R)-N-Benzoyl-2'-deoxy-2'-fluoro-2'-methylcytidine 3',5'-dibenzoate

- 3-Benzyloxy-5- bromobenzotrifluoride

- 4-(Benzyloxy)-5-bromo-2-fluorophenylboronic acid

- 1-(Benzyloxy)-2-bromo-4-(trifluoromethyl) benzene

- 1-(benzyloxy)-4-chloro-2,3- difluorobenzene

- 2-(benzyloxy)-1,5-dichloro- 3-fluorobenzene

- 1-Benzyloxy- 3-fluorobenzene

- Carboxes

- 2-Azaspiro[3.3]heptane-6-carboxylic acid trifluoroacetate

- Acetic acid 2-ethylphenyl ester

- 3-Acetyl-4-hydroxy-6-methyl-2h- pyran-2-one

- 8-Aminoquinoline-3-carboxylic acid

- 5-Amino-2-phenyl-2h-1,2,3-triazole-4-carboxylic acid

- 2-Acetylsulfanyl-2-methylpropionic acid ethyl ester

- Ammonium sebacate

- 4-Acetoxymethylbenzoic acid

- 5-Aminopyrazolo[1,5-a]pyridine-3-carboxylic acid hydrochloride

- Acetic acid 3-buten-1-yl ester

- 8-Aminoquinoline-4-carboxylic acid

- Ammonium 2,4-dichlorophenoxyacetate

- Aceclofenac ethyl ester.

- Acepromazine maleate

- 2-Acetamidoacrylic acid

- 5-Acetamidoanthranilic acid

- 2-acetamidoisophthalic acid

- 4-Acetamidobenzoic acid

- 4-Acetamidobicyclo[2.2.2]octane-1-carboxylic acid

- 2'-Acetamidobiphenyl-3-carboxylic acid

- 3'-Acetamidobiphenyl-3-carboxylic acid

- 4'-Acetamidobiphenyl-3-carboxylic acid

- 4-Acetamidobutyric acid

- 2-Acetamido-5-chlorobenzoic acid

- 4-Acetamido-5-chloro-2-methoxybenzoic acid

- 1-Acetamidocyclopentane-1-carboxylic acid

- 2-Acetamido-2-deoxy-1-thio-beta-D-glucopyranose 3,4,6-triacetate

- (1S,2S,3R,4R)-3-((S)-1-Acetamido-2-ethylbutyl)-4-guanidino-2-hydroxycyclopentane-1-carboxylic acid trihydrate

- N-(2-Acetamido)iminodiacetic acidmonosodium salt

- 4-Acetamido-2-methylbenzoic acid

- 3-Acetamido-3-methylbutanoic acid

- S-Acetamidomethyl-3-mercaptopropionic acid

- 3-Acetamido-2-methylphenyl acetate

- (4-Acetamidophenoxy)acetic acid

- 2-(2-Acetamidophenoxy)acetic acid

- 4-Acetamidophenylacetic acid ethyl ester

- 4-(4-Acetamidophenyl)-4-oxobutanoic acid

- 5-Acetamidopyridine-2-carboxylic acid

- 4-Acetamido-1h-pyrrole-2-carboxylic acid

- 3-Acetamido-2,4,6-triiodo-5-(N-methylacetamido)benzoic acid

- Acetic acid acetoxy-(4-chlorosulfonylphenyl)methyl ester

- Acetic acid 4-chloro-3-methylphenyl ester

- Acetic acid, 2-[[4-(4-cyclopropyl-1-naphthalenyl)-4h-1,2,4-triazol-3-yl]thio]-, methyl ester

- Acetic acid-d

- Acetic acid 4-ethylphenyl ester

- Acetic acid n-heptadecyl ester

- Acetic acid 5-hexen-1-yl ester

- Acetic acid, 2-hydrazinyl-2-imino-, ethyl ester

- Acetic acid 7-methoxy-4-oxo-1,4-dihydro-quinazolin-6-yl ester

- ACETIC ACID 8-NONEN-1-YL ESTER

- tert-Butyl 3-carbamimidoylazetidine-1-carboxylate acetate

- Acetic acid trans-2-hepten-1-yl ester

- Acetic acid tridecyl ester

- Acetic acid 2-vinylphenyl ester

- 3-Oxo- N- phenylbutanamide

- Acetoacetic acid n-butyl ester

- Acetoacetic acid hexyl ester

- Acetoacetic acid isoamyl ester

- Acetoacetic acid n-octyl ester

- Acetoacetic acid n-propyl ester

- Acetoacetic acid sec-butyl ester

- Acetoacetyl-l-carnitine chloride

- Acetochloro - alpha- d- mannose

- diethyl 2-(2-oxopropyl)malonate

- Diethyl 2-(2-oxopropyl)succinate

- Acetoxime benzoate

- Acetoxyacetic acid

- Acetonyl acetate

- 2-Acetylphenyl acetate

- 3-acetylphenyl acetate

- Acetoxyacetyl chloride

- 3-Acetoxybenzoic acid

- 4-Acetoxybenzoic acid

- (2-cyanophenyl) acetate

- 6-Acetoxy-n-caproic acid methyl ester

- 3-chloro-2-oxopropyl acetate

- 2-Acetoxy-2-(4-chlorophenyl)acetic acid

- 3-(4-ACETOXYPHENYL)ACRYLIC ACID

- 4-Acetoxy-3-(cyclopropylmethoxy)benzoic acid

- 2-(p-Tolyloxy)ethyl acetate

- 7-Acetoxy-1- heptene

- (R)-2-Acetoxy-3-(hexadecyloxy)propyl (2-(trimethylammonio)ethyl) phosphate

- 2,3-Dihydro-1H-inden-1-yl acetate

- 1-Chloro-2-methyl-1-oxopropan-2-yl acetate

- 4-(Acetyloxy)-3-methoxybenzoic acid

- ((2R,3S)-3-Acetoxy-6-methoxy-3,6-dihydro-2h-pyran-2-yl)methyl acetate

- 3-acetyloxy-2-methylbenzoic acid

- 7-Acetoxy-4- methylcoumarin

- (2-methylnaphthalen-1-yl) Acetate

- (Z)-4-Acetoxy-3-(4-(methylsulfonyl) phenyl)-2-phenylbut-2-enoic acid

- (2S,3S,4S,5R,6R)-6-(Acetoxymethyl)-3-(((trifluoromethyl)sulfonyl)oxy)tetrahydro-2H-pyran-2,4,5-triyl triacetate

- 6-Acetoxy-2-naphthoic acid

- 8-Acetoxy-1- octene

- 3-Acetoxy-2-phenylpropanoic acid

- (+/-)-2-Acetoxypropionic acid

- 2-Acetoxypropionyl chloride

- Succinimidyl acetate

- Acetrizoic acid

- Acetylacrylic acid methyl ester

- 5'-O- Acetyladenosine

- 3-[(Acetylamino)methyl]adamantane-1-carboxylic acid

- 4-(3-Acetylaminophenyl)benzoic acid

- 1-[3-(Acetylamino)phenyl]-5-oxopyrrolidine-3-carboxylic acid

- 1-[4-(Acetylamino)phenyl]-5-oxopyrrolidine-3-carboxylic acid

- 3-(Acetylamino)thiophene-2-carboxylic acid

- 4-(4-Acetylanilino)-4-oxobutanoic acid

- 1-Acetylazepane-4-carboxylic acid

- 1-Acetyl-azetidine-3-carboxylic acid

- 1-Acetyl-azetidine-3-carboxylic acid methyl ester

- 1-Acetylazetidin-3-yl acetate

- 2-Acetylbenzenecarbo nitrile

- 3-Acetylbenzo[f] coumarin

- 2-Acetylbenzoic acid

- 3-Acetylbenzoic acid

- 4-Acetylbenzoic acid

- 3- Acetylbenzonitrile

- 4- Acetylbenzonitrile

- 5-Acetyl-2-benzyloxy-benzoic acid

- 3'-Acetylbiphenyl-3-carboxylic acid

- 4'-Acetylbiphenyl-3-carboxylic acid

- 1'-Acetyl-[1,4'-bipiperidine]-4-carboxylic acid

- 4-Acetylbutyric acid

- 2- Acetylbutyrolactone

- Acetyl-l-carnitine hydrochloride

- N'-Acetyl-2- chloroacetohydrazide

- 4-Acetyl-2-chlorobenzoic acid

- 4-Acetyl-3-chlorobenzoic acid

- 3-Acetyl-3-chloro-dihydro-furan- 2-one

- Acetylcholine bromide

- Acetylcholine perchlorate

- 3- Acetylcoumarin

- 1-Acetyl-cyclopropanecarboxylic acid methyl ester

- 3-O-Acetyl-1,2:5,6-di-o-isopropylidene-alpha-d- glucofuranose

- 3-Acetyl-2,4-dimethyl-5- carbethoxypyrrole

- (1S,3R)-3-Acetyl-2,2-dimethylcyclobutane-1-carboxylic acid

- 5-Acetyl-2,2-dimethyl-1,3-dioxane-4,6- dione

- 4-Acetyl-3,5-dimethyl-1h-pyrrole-2-carboxylic acid

- 5-Acetyl-2,4-dimethyl-1h-pyrrole-3-carboxylic acid

- 4-O-Acetyl-3,6-di-o-(tert-butyldiphenylsilyl)-d- galactal

- 5-Acetyl-2-ethoxybenzoic acid

- 5-Acetyl-2-ethoxy-benzoic acid methyl ester

- 4-(2-Acetylhydrazino)-4-oxobutanoic acid

- 3-Acetyl-4-hydroxy-2H-chromen- 2-one

- 6-O-Acetyl-4-hydroxy-7-methoxy quinazoline

- 3-Acetylindolizine-1-carboxylic acid

- 3-Acetyl-4-isopropoxybenzoic acid

- 5'-Acetyl-2',3'- isopropylideneadenosine

- O-Acetyl mandelic acid

- 5-Acetyl-2-(4-methoxy-benzyloxy)-benzoic acid methyl ester

- 3-Acetyl-7-methoxychromen-2- one

- 4-Acetyl-2-methoxyphenyl acetate

- 5-Acetyl-2-methoxyphenyl acetate

- (5-Acetyl-2-methoxyphenyl)acetic acid

- 3-[3-Acetyl-5-(4-methoxyphenyl)-2-methyl-1h-pyrrol-1-yl]propanoic acid

- N- Acetyl-2-methylalanine

- 2-[Acetyl(methyl)amino]benzoic acid

- 1-Acetyl-2-methylazepane-2-carboxylic acid

- 1-Acetyl-4-methylazepane-4-carboxylic acid

- 4-Acetyl-2-methylbenzoic acid

- 4-Acetyl-2-methyl-benzoic acid benzyl ester

- 3-Acetyl-7-methyl-2h-chromen-2- one

- 3-Acetyl-6-methyl-2-oxo-2h-pyran-4-yl difluoridoborate

- (3-Acetyl-2-methyl-5-phenyl-1h-pyrrol-1-yl)acetic acid

- 3-(3-Acetyl-2-methyl-5-phenyl-1h-pyrrol-1-yl)propanoic acid

- 6-Acetyl-7-methylpyrazolo[1,5-a]pyrimidine-3-carboxylic acid

- 4-Acetyl-1-methyl-1h-pyrrole-2-carboxylic acid

- 1-Acetyloxy-2,5-dioxopyrrolidine-3-sulfonic acid

- (2-Acetyl-phenoxy)-acetic acid

- (3-Acetylphenoxy)acetic acid

- 4-Acetylphenoxyacetic acid

- (3-Acetyl-phenoxy)-acetic acid tert-butyl ester

- (4-Acetyl-phenoxy)-acetic acid tert-butyl ester

- 4-(4-Acetyl-phenoxy)-butyric acid

- 2-(4-Acetylphenoxy)-n,n- diethylacetamide

- 2-(4-Acetylphenoxy)-n,n- dimethylacetamide

- 5-[(2-Acetylphenoxy)methyl]-2-furoic acid

- 5-[(4-Acetylphenoxy)methyl]-2-furoic acid

- 2-(4-Acetylphenoxy)-n- phenylacetamide

- 4-Acetylphenyl acetate

- 2-([(3-Acetylphenyl)amino]carbonyl)cyclohexanecarboxylic acid

- 2-([(4 Acetylphenyl)amino]carbonyl) cyclohexanecarboxylic acid

- 6-([(3-Acetylphenyl)amino]carbonyl)cyclohex-3-ene-1-carboxylic acid

- 6-([(4-Acetylphenyl)amino]carbonyl)cyclohex-3-ene-1-carboxylic acid

- 2-(3-Acetylphenyl)benzoic acid

- 3-(2-Acetylphenyl)benzoic acid

- 4-(2-Acetylphenyl)benzoic acid

- 4-(3-Acetylphenyl)benzoic acid

- 4-(4-Acetylphenyl)benzoic acid

- 3-(3-Acetylphenyl) benzonitrile

- 3-(4-Acetylphenyl) benzonitrile

- 4-(2-Acetylphenyl)-2-chlorobenzoic acid

- 4-(4-Acetylphenyl)-2-chlorobenzoic acid

- 4-Acetylphenyl (3,4-dichlorophenyl) carbamate

- 4-Acetylphenyl dimethylcarbamate

- 2-(4-Acetylphenyl)-1,3-dioxoisoindoline-5-carboxylic acid

- 3-Acetylphenyl ethyl(methyl) carbamate

- 3-(3-Acetylphenyl)-4-fluorobenzoic acid

- 3-(4-Acetylphenyl)-4-fluorobenzoic acid

- 5-(4-Acetylphenyl)-2-furoic acid

- (4-Acetylphenyl) n-methylcarbamate

- 1-Acetyl-4-piperidineacetic acid

- 1-Acetylpiperidine-4-carbonyl chloride

- (S)-1-Acetylpiperidine-3-carboxylic acid

- 1-Acetylpiperidine-3-carboxylic acid

- 1-Acetylpiperidine-4-carboxylic acid

- 6-[(1-Acetylpiperidin-4-yl)amino]pyrimidine-4-carboxylic acid lithium salt

- 5-Acetylpyrazine-2-carboxylic acid

- 3-Acetyl-1h-pyrazole-5-carboxylic acid

- 5-Acetyl-2H-pyrazole-3-carboxylic acid ethyl ester

- 6-Acetyl-2-pyridinecarboxylic acid

- 4-Acetyl-1h-pyrrole-2-carboxylic acid

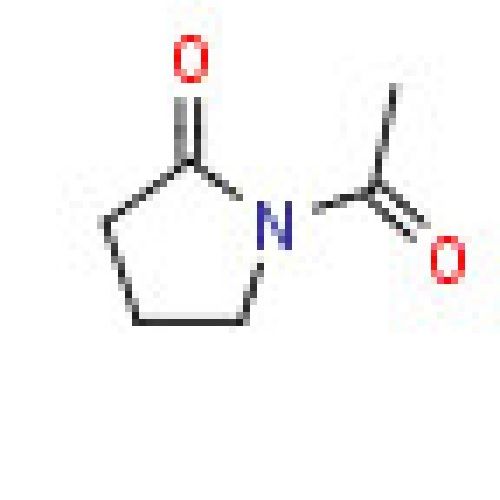

- 1-Acetyl-2- pyrrolidone

- 6-Acetylquinoline-3-carboxylic acid

- 7-Acetylquinoline-3-carboxylic acid

- Acetylsalicylic anhydride

- Acetylsalicylsalicylic acid

- 4-(Acetylsulfanyl)butanoic acid

- S-Acetylthioacetic acid

- 2-[(Acetylthio)methyl]-3-phenylpropionic acid

- (2S)-3-Acetylthio-2-methylpropionic acid

- 2-(Acetylthio)succinic anhydride

- 3'-O- Acetylthymidine

- 9-Acridinecarboxylic acid

- 2- Propenamide

- 6-Acrylamidohexanoic acid

- Acrylic acid barium salt monomer

- Acrylic acid isoamyl ester

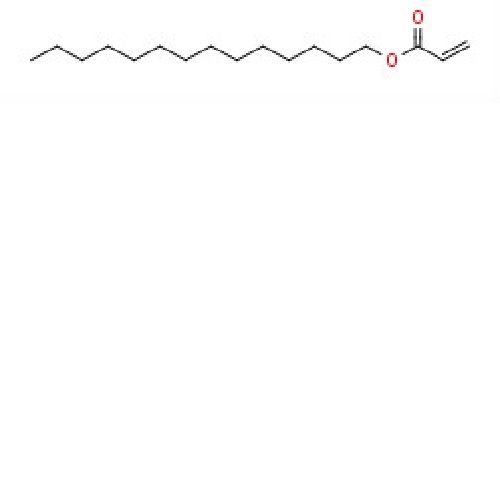

- Acrylic acid tetradecyl ester

- Acrylic anhydride

- 4-(6-Acryloxy-hex-1-yl-oxy)phenyl 4-(hexyloxy) benzoate

- (3-Acryloxypropyl)tris (trimethylsiloxy)silane

- N- Acryloxysuccinimide

- 4- Acryloyloxybenzophenone

- 4-((6-(Acryloyloxy)hexyl)oxy)benzoic acid

- 4'-[(6-Acryloyloxy)hexyloxy]-4- biphenylcarbonitrile

- 1-Adamantaneacetic acid

- 1- Adamantanecarboxamide

- Adamantane-2-carboxylic acid

- 1-Adamantanecarboxylic acid

- Adamantane-1-carboxylic acid methyl ester

- 1,3-Adamantanediacetic acid

- 1,3-Adamantanedicarboxylic acid

- 2-Adamantanone-5-carboxylic acid

- (E)-3-((1r,3r,5R,7S)-Adamantan-2-ylidene)-4- (1-(2,5-dimethylfuran-3-yl)ethylidene)dihydrofuran-2,5-dione

- Adamantan-1-ylmethyl acetate

- [2-(1-Adamantyl)ethoxy]acetic acid

- 5-(1-Adamantyl)-2-furoic acid

- 1-Adamantyl methacrylate

- 3-(1-Adamantyl)-4-methoxybenzoic acid

- 5-(1-Adamantyl)-2-methoxybenzoic acid

- 1-(2-Adamantyl)-4-nitro-1h-pyrazole-3-carboxylic acid

- (1-Adamantyloxy)acetic acid

- [4-(1-Adamantyl)phenoxy]acetic acid

- 4-(1-Adamantyl)phenyl acetate

- 3-(1-Adamantyl)-1-phenyl-1h-pyrazole-4-carboxylic acid

- (2E)-3-[3-(1-Adamantyl)-1-phenyl-1h-pyrazol-4-yl]acrylic acid

- 3-(1-Adamantyl)propanoic acid

- 2-(1-Adamantyl)quinoline-4-carboxylic acid

- (1-Adamantylthio)acetic acid

- Adipic acid dibenzyl ester

- Adipic acid monobenzyl ester

- Adipic acid monoethyl ester

- Adipic anhydride

- Adipic dihydrazide

- Z-Aeeac-oh dcha

- Afatinib dimaleate

- Ahu-377 hemicalcium salt

- Alantola ctone

- Allyl acetoacetate

- Allyl amyl glycolate

- Allyl benzoate

- 3-Allyl-3-hydroxyazetidine-1-carboxylic acid tert-butyl ester

- 3-Allyl-4-methoxybenzoic acid

- Allyl 2-oxocyclohexanecarboxylate

- Allyl 2-oxocyclopentanecarboxylate

- 1-Allyl-5-oxopyrrolidine-3-carboxylic acid

- 3-Allyloxy-azetidine-1-carboxylic acid tert-butyl ester

- 4-(Allyloxy)-1-benzofuran-6-carboxylic acid

- 3-(Allyloxy)benzoic acid

- 4-(Allyloxy)benzoic acid

- 4-(Allyloxy) benzonitrile

- 4-Allyloxycarbonylamino-bicyclo[2.2.2]octane-1-carboxylic acid

- 1-Allyloxycarbonylamino-cyclopentanecarboxylic acid

- 1-Allyloxycarbonylamino-cyclopropanecarboxylic acid

- (2-Allyloxy-ethoxy)-acetic acid benzyl ester

- 3-Allyloxyphenylacetic acid

- 3-Allyloxypropionic acid

- 2-(4-Allyloxy-pyrazol-1-yl)-2-methyl-propionic acid

- [(4-Allyl-5-phenyl-4h-1,2,4-triazol-3-yl)thio]acetic acid

- 1-Allylpiperidine-3-carboxylic acid

- 1-Allylpiperidine-4-carboxylic acid

- Allylsuccinic anhydride

- 2-Allyl-1-(tert-butoxycarbonyl)-2,3-dihydro-1H-benzo[d]imidazole-2-carboxylic acid

- 1-Allyl 4-tert-butyl piperazine-1,4-dicarboxylate

- (Allylthio)acetic acid

- 2-(Allylthio)propanoic acid

- Aloc-o2oc-oh dcha

- Alpha- acetoxyphenylacetonitrile

- (1Alpha,8alpha,9alpha)-bicyclo[6.1.0]non-4-ene-9-carboxylic acid ethyl ester

- (1Alpha,2alpha,4alpha)-1,2,4-cyclohexanetricarboxylic acid

- Alpha,alpha'- dilaurin

- Alpha,alpha-dimethyl-gamma- butyrolactone

- Alpha- angelicalactone

- Alpha-d-cellobiose octaacetate

- Alpha-cyanocinnamic acid

- Alpha-cyanocinnamic acid ethyl ester

- alpha-Cyclopentylmandelic acid

- Alpha-cyclopentylphenylacetic acid

- Alpha-(Fmoc-amino)-omega-(succinimidyl propionate) tetra(ethylene glycol)

- Alpha-d-galacturonic acid hydrate

- 2-O-Alpha-d-glucopyranosyl-l-ascorbic acid

- Alpha-hydroxy-gamma- butyrolactone

- Alpha-ketobutyric acid sodium salt

- Alpha-ketoglutaric acid sodium salt

- H-Alpha-me-leu- oh

- (R)-2-AMINO-2,4-DIMETHYLPENTANOIC ACID

- Alpha-methoxyphenylacetic acid sodium salt

- Alpha-methylcinnamic acid

- Alpha-methylene-gamma- butyrolactone

- Alpha-methylene-gamma- valerolactone

- Alpha-methyl-gamma- butyrolactone

- Alpha-phenylcinnamic acid

- Alpha-(phenylthio)phenylacetic acid

- L-Alpha- phosphatidylinositol

- 2H-Pyran- 2-one

- D-Alpha-tocopheryl acetate

- 4-Amidinobenzoic acid hydrochloride

- 2-Aminoadamantane-2-carboxylic acid

- 3-Amino-1-adamantanecarboxylic acid

- 3-Amino-1-adamantanecarboxylic acid hydrochloride

- 6-Amino-3-aza-bicyclo[3.1.1]heptane-3-carboxylic acid

- 6-Amino-2-azaspiro[3.3]heptane-6-carboxylic acid

- 6-Amino-2-azaspiro[3.3]heptane-6-carboxylic acid dihydrochloride

- 6-Amino-2-aza-spiro[3.3]heptane-2-carboxylic acid tert-butyl ester

- 6-Amino-2-aza-spiro[3.3]heptane-2,6-dicarboxylic acid 2-tert-butyl ester

- 2-Amino-7-azaspiro[3.5]nonane-7-carboxylic acid tert-butyl ester

- 2-Amino-6-aza-spiro[3.4]octane-6-carboxylic acid tert-butyl ester

- 3-Amino-azepane-1-carboxylic acid tert-butyl ester

- 3-Aminoazetidine-3-carboxylic acid hydrochloride

- 4-Aminobenzene-1,3-dicarboxylic acid

- 4-Amino-1-benzofuran-2-carboxylic acid

- 5-Amino-1-benzofuran-2-carboxylic acid

- 5-Amino-1h-benzoimidazole-2-carboxylic acid methyl ester

- 2-Aminobenzophenone-2'-carboxylic acid

- 5-Amino-1-benzothiophene-2-carboxylic acid

- 3-(4-Aminobenzylamino)pyrrolidine-1-carboxylic acid tert-butyl ester hydrochloride

- 3-Amino-5-(4-benzyloxyphenyl)thiophene-2-carboxylic acid methyl ester

- 3-Amino-1-benzylpyrrolidine-3-carboxylic acid

- 5-Amino-1-benzyl-1,2,3,6-tetrahydro-pyridine-4-carboxylic acid ethyl ester

- 5-Amino-1-benzyl-1h-1,2,3-triazole-4-carboxylic acid

- 3-Aminobicyclo[2.2.1]hept-5-ene-2-carboxylic acid hydrochloride

- 4-Aminobicyclo[2.2.2]octane-1-carboxylic acid

- 4-Amino-bicyclo[2.2.2]octane-1-carboxylic acid cyclopropylamide, hydrochloride

- 4-Amino-bicyclo[2.2.2]octane-1-carboxylic acid cyclopropylmethyl-amide, hydrochloride

- 4-Amino-bicyclo[2.2.2]octane-1-carboxylic acid methylamide, hydrochloride

- 3-Aminobicyclo[1.1.1]pentane-1-carboxylic acid hydrochloride

- 1'-Amino-1,1'-bi(cyclopropyl)-1-carboxylic acid hydrochloride

- 2'-Aminobiphenyl-3-carboxylic acid

- 3'-Aminobiphenyl-3-carboxylic acid

- 4'-Aminobiphenyl-3-carboxylic acid

- 2'-Amino-[1,1'-biphenyl]-4-carboxylic acid hydrochloride

- 3'-Amino-[1,1'-biphenyl]-3-carboxylic acid hydrochloride

- 4'-Amino-[1,1'-biphenyl]-4-carboxylic acid hydrochloride

- 3'-Amino-biphenyl-3-carboxylic acid methyl ester hydrochloride

- (1S,3R,4R)-4-Amino-3-(boc-amino)-cyclohexanecarboxylic acid ethyl ester

- 4-Amino-1-Boc-4-piperidinedicarboxylic acid ethyl ester

- (3R,4S)-4-Amino-1-boc-3-pyrrolidinecarboxylic acid ethyl ester hydrochloride

- 2-Amino-4- bromobenzamide

- 3-Amino-6-bromo-benzofuran-2-carboxylic acid methyl ester

- 3-Amino-5-bromobenzoic acid

- 4-Amino-5-bromo-2-methoxybenzenecarboxylic acid

- 4-Amino-8-bromo-6-methylquinoline-3-carboxylic acid ethyl ester

- 5-Amino-1-(4-bromophenyl)-1H-pyrazole-4-carboxylic acid

- 2-Amino-3-bromopyrazine-5-carboxylic acid

- 3-Amino-4-bromo-1h-pyrazole-5-carboxylic acid

- 4-Amino-5-bromopyridine-2-carboxylic acid

- 3-Amino-6-bromopyridine-2-carboxylic acid ethyl ester

- 3-Amino-5-bromopyridine-2-carboxylic acid hydrochloride

- 3-Amino-5-bromo-pyridine-2-carboxylic acid isopropyl ester

- 4-Amino-6-bromoquinoline-3-carboxylic acid

- 4-Amino-8-bromoquinoline-3-carboxylic acid ethyl ester

- 3-Amino-5-bromo-thiophene-2-carboxylic acid methyl ester hydrochloride

- 2-Amino-3-carbamoyl-4,7-dihydro-5h-thieno[2,3-c]pyridine-6-carboxylic acid benzyl ester

- 2-Amino-3-carbamoyl-4,7-dihydro-5h-thieno[2,3-c]pyridine-6-carboxylic acid tert-butyl ester

- N-[3-(Aminocarbonothioyl) phenyl]cyclopropanecarboxamide

- 4-[(Aminocarbonyl)amino]benzoic acid

- (1S,2R,3R,4S)-3-(Aminocarbonyl)bicyclo[2.2.1]hept-5-ene-2-carboxylic acid

- 3-Aminocarbonyl-1-Boc- pyrrolidine

- 2-(Aminocarbonyl)cyclopropanecarboxylic acid

- 2-[4-(Aminocarbonyl)phenoxy]quinoline-4-carboxylic acid

- 3-(3-Aminocarbonylphenyl)benzoic acid

- 4-(3-Aminocarbonylphenyl)benzoic acid

- 1-[4-(Aminocarbonyl)phenyl]-5-oxopyrrolidine-3-carboxylic acid

- 5-(Aminocarbonyl)thiophene-2-carboxylic acid

- 4-Amino-4-carboxytetrahydrothiopyran hydrochloride

- 3-Amino-4-chloro-benzofuran-2-carboxylic acid methyl ester

- 4-Amino-2- chlorobenzonitrile

- 4-Amino-3-([(2-chlorobenzyl) amino]carbonyl ) isothiazole-5-carboxylic acid

- 6-Amino-5-chloro-2-cyclopropylpyrimidine-4-carboxylic acid

- 4-Amino-5-chloro-2,3-dihydrobenzofuran-7-carboxylic acid

- 5-Amino-1-(2-chloro-5-fluorophenyl)-1h-pyrazole-4-carboxylic acid

- 5-Amino-1-(4-chloro-2-fluorophenyl)-1h-pyrazole-4-carboxylic acid

- 6-Amino-5-(4-chloro-3-methylphenyl)pyridine-3-carboxylic acid

- 1-[2-Amino-1-(2-chloro-phenyl)-ethyl]-pyrrolidine-3-carboxylic acid

- 5-Amino-1-(4-chlorophenyl)-1h-pyrazole-4-carboxylic acid

- 5-Amino-4-chloro-1h-pyrazole-3-carboxylic acid

- 2-Amino-6-chloropyridine-4-carboxylic acid

- 3-Amino-2-chloroisonicotinic acid

- 3-Amino-5-chloropyridine-2-carboxylic acid

- 3-Amino-6-chloropyridine-2-carboxylic acid

- 5-amino-2-chloropyridine-3-carboxylic acid

- 3-Amino-5-chloropyridine-2-carboxylic acid hydrochloride

- 3-Amino-6-chloropyridine-2-carboxylic acid hydrochloride

- 2-Amino-5-chloropyridin-3- ol

- 6-Amino-5-chloro-4-pyrimidinecarboxylic acid

- 2-Amino-5-chloropyrimidine-4-carboxylic acid hydrochloride

- 3-Amino-6-chloro-thieno[3,2-b]pyridine-2-carboxylic acid methyl ester

- 4-Amino-5-chlorothiophene-2-carboxylic acid methyl ester

- 2-Amino-5- cyanobenzamide

- 3-Aminocyclobutanecarboxylic acid

- 1-Amino-cyclobutane-carboxylic acid ethyl ester hydrochloride

- 1-Aminocyclobutanecarboxylic acid hydrochloride

- 3-Aminocyclobutanecarboxylic acid hydrochloride

- 1-Amino-cyclobutane-carboxylic acid methyl ester hydrochloride

- 3-Aminocyclobutanecarboxylic acid tert-butyl ester

- 7-Amino-2-cyclobutyl[1,2,4]triazolo[1,5-a]pyrimidine-6-carboxylic acid

- 1-Amino-1-cycloheptanecarboxylic acid

- (1R,2R)-2-Aminocyclohexanecarboxylic acid

- (1S,2S)-2-Aminocyclohexanecarboxylic acid

- (1S,3S)-3-Aminocyclohexanecarboxylic acid

- 3-Aminocyclohexanecarboxylic acid

- (1R,3S)-3-Aminocyclohexanecarboxylic acid hydrochloride

- (1S,3R)-3-Aminocyclohexane-1-carboxylic acid hydrochloride

- (1S,3S)-3-Aminocyclohexane-1-carboxylic acid hydrochloride

- 2-Aminocyclohexane-1-carboxylic acid hydrochloride

- (1R,2S)-(+)-2-Aminocyclohex-3-enecarboxylic acid hydrochloride

- (1S,2S)-2-Aminocyclopentanecarboxylic acid

- (1R,2S)-(-)-2-Amino-1-cyclopentanecarboxylic acid hydrochloride

- (1R,3R)-3-Aminocyclopentanecarboxylic acid hydrochloride

- (1S,3S)-3-Aminocyclopentane-1-carboxylic acid hydrochloride

- (1S,4R)-4-Aminocyclopent-2-enecarboxylic acid hydrochloride

- 5-Amino-3,6-dichloropyrazine-2-carboxylic acid

- 3-Amino-2,6-dichloropyridine-4-carboxylic acid

- 1-Amino-3,3-difluorocyclobutanecarboxylic acid

- 1-Amino-4,4-difluorocyclohexane-1-carboxylic acid

- (1R)-1-Amino-2,2-difluorocyclopropane-1-carboxylic acid

- 1-Amino-2,2-difluorocyclopropane-1-carboxylic acid

- (2S,4R)-4-Amino-2-difluoromethyl-pyrrolidine-1-carboxylic acid tert-butyl ester

- 5-Amino-1-(2,4-difluorophenyl)-1h-pyrazole-4-carboxylic acid

- 5-Amino-1-(3,5-difluorophenyl)-1h-pyrazole-4-carboxylic acid

- 2-Amino-4,7-dihydro-5-[2-[4-(carboxy)phenyl]ethyl]-4-oxo-3h-pyrrolo[2,3-d]pyrimidine hydrate

- 6-Amino-1,4-dihydro-4-oxo-2-quinolinecarboxylic acid methyl ester

- 2-Amino-7,8-dihydro-5h-pyrido[4,3-d]pyrimidine-6-carboxylic acid benzyl ester

- 2-Amino-5,8-dihydro-6h-pyrido[3,4-d]pyrimidine-7-carboxylic acid tert-butyl ester

- 2-Amino-7,8-dihydro-6h-pyrido[3,2-d]pyrimidine-5-carboxylic acid tert-butyl ester

- 2-Amino-4,7-dihydro-5h-thieno[2,3-c]pyran-3-carboxylic acid tert-butyl ester

- 2-Amino-4,7-dihydro-5h-thieno[2,3-c]pyridine-3,6-dicarboxylic acid 6-benzyl ester 3-ethyl ester

- 2-Amino-4,7-dihydro-5h-thieno[2,3-c]pyridine-3,6-dicarboxylic acid 6-benzyl ester 3-methyl ester

- 2-Amino-4,7-dihydro-5h-thieno[2,3-c]pyridine-3,6-dicarboxylic acid di-tert-butyl ester

- 2-Amino-4,7-dihydro-5h-thieno[2,3-c]thiopyran-3-carboxylic acid ethyl ester

- 2-Amino-5,8-dimethoxy-1,2,3,4-tetrahydronaphthalene-2-carboxylic acid

- 3-Amino-4,6-dimethylthieno[2,3-b]pyridine-2-carboxylic acid

- 2-Amino-4,5-dimethylthiophene-3-carboxylic acid Synonyms : 2-amino-4,5-dimethylthiophene-3-carboxylic acid

- 2-Amino-4,5-dimethyl-thiophene-3-carboxylic acid methyl ester

- 1-(2-Aminoethyl)cyclopropanecarboxylic acid

- 1-(2-Aminoethyl)cyclopropane-1-carboxylic acid hydrochloride

- 4-(2-Aminoethyl)-5-(2-furyl)-1,2-dihydro-3h- pyrazol-3-one

- 2-Amino-4-ethyl-5-methylthiophene-3-carboxylic acid methyl ester

- 2-Amino-5-ethylthiophene-3-carboxylic acid methyl ester

- 4-Amino-2-ethylthiopyrimidine-5-carboxylic acid

- 4-Amino-2-(ethylthio)-5-pyrimidinecarboxylic acid ethyl ester

- 1-(2-Aminoethyl)-1h-1,2,3-triazole-4-carboxylic acid hydrochloride

- 2-Amino-5- fluorobenzamide

- 3-Amino-4-fluoro-benzofuran-2-carboxylic acid methyl ester

- 3-Amino-6-fluoro-benzofuran-2-carboxylic acid methyl ester

- 3-Amino-2-fluorobenzoic acid

- 4-Amino-6-fluorocinnoline-3-carboxylic acid

- 1-Amino-3-fluoro-cyclobutanecarboxylic acid

- (2R,4R)-4-Amino-6-fluoro-2-methylchroman-4-carboxylic acid

- 3-Amino-5-(3-fluoro-2-methylphenyl)benzoic acid

- 1-[2-Amino-1-(4-fluoro-phenyl)-ethyl]-pyrrolidine-3-carboxylic acid

- 5-Amino-1-(2-fluorophenyl)-1h-pyrazole-4-carboxylic acid

- 5-Amino-1-(4-fluorophenyl)-1h-pyrazole-4-carboxylic acid

- (1R,3S,4S)-3-Amino-4-hydroxy-cyclohexanecarboxylic acid ethyl ester hydrochloride

- (1S,3R,4R)-3-Amino-4-hydroxy-cyclohexanecarboxylic acid ethyl ester hydrochloride

- 2-Amino-4-hydroxy-7,8-dihydro-5h-pyrido[4,3-d]pyrimidine-6-carboxylic acid tert-butyl ester

- 5-Amino-1-(2-hydroxyethyl)pyrazole-4-carboxylic acid

- 1-Amino-3-(hydroxymethyl)cyclobutane-1-carboxylic acid

- 4-Amino-2-hydroxypyrimidine-5-carboxylic acid hydrobromide

- 3-Amino-3-imino-propanoic acid, ethyl ester hydrochloride

- 1-Aminoindan-1-carboxylic acid

- 2-Amino-2-indancarboxylic acid

- 3-Amino-1H-indazole-5-carboxylic acid

- 3-Amino-1h-indazole-4-carboxylic acid

- 3-Amino-1h-indazole-6-carboxylic acid

- 5-Amino-1H-indazole-3-carboxylic acid

- 6-Amino-1h-indazole-7-carboxylic acid

- 4-Amino-5-iodo-2-methoxybenzenecarboxylic acid

- 3-Amino-6-iodopyrazine-2-carboxylic acid

- 5-Amino-6-iodo-2-pyrazinecarboxylic acid

- N-(6-Amino-1-isobutyl-2,4-dioxo-1,2,3,4-tetrahydro-pyrimidin-5-yl) -4-chloro-n-(2-methoxy-ethyl)-butyramide

- 3-Aminoisoquinoline-6-carboxylic acid

- 4-Aminoisoquinoline-6-carboxylic acid

- 4-Aminoisoquinoline-8-carboxylic acid

- 7-Aminoisoquinoline-4-carboxylic acid

- 8-Aminoisoquinoline-5-carboxylic acid

- 3-Aminoisoquinoline-8-carboxylic acid hydrochloride

- 4-Amino-2-mercaptopyrimidine-5-carboxylic acid

- 3-Amino-4- methanesulfonylbenzonitrile

- 2-Amino-5-(4-methoxy-phenylcarbamoyl)-4-methyl-thiophene-3-carboxylic acid ethyl ester

- 1-[2-Amino-1-(2-methoxy-phenyl)-ethyl]-pyrrolidine-3-carboxylic acid

- 4-Amino-1-(4-methoxyphenyl)-1h-pyrazole-3-carboxylic acid

- 5-Amino-1-(4-methoxyphenyl)-1h-pyrazole-4-carboxylic acid

- 6-Amino-5-methoxy-pyridine-2-carboxylic acid methyl ester

- 4-Amino-6-methoxyquinoline-3-carboxylic acid ethyl ester

- 2-Amino-6-methoxy-1,2,3,4-tetrahydro-naphthalene-2-carboxylic acid

- 2-Amino-8-methoxy-1,2,3,4-tetrahydro-naphthalene-2-carboxylic acid

- 2-Aminomethyl-7-azaspiro[3.5]nonane-7-carboxylic acid tert-butyl ester

- 2-Amino-3- methylbenzamide

- 3-(Aminomethyl)cyclobutanecarboxylic acid hydrochloride

- 1-Aminomethyl-cyclohexanecarboxylic acid methyl ester hydrochloride

- 1-Aminomethyl-3,4-dihydro-1h-isoquinoline-2-carboxylic acid tert-butyl ester oxalate

- 3-Aminomethyl-3-fluoropiperidine-1-carboxylic acid tert-butyl ester

- 5-(Aminomethyl)furan-2-carboxylic acid hydrochloride

- 5-Amino-1-methyl-1h-indazole-3-carboxylic acid

- (R)-3-Aminomethyl-morpholine-4-carboxylic acid tert-butyl ester

- 3-Aminomethyl-morpholine-4-carboxylic acid tert-butyl ester

- 1-Aminomethyl-2-oxa-5-aza-bicyclo[2.2.1]heptane-5-carboxylic acid tert-butyl ester

- 7-Aminomethyl-6-oxa-2-aza-spiro[3.4]octane-2-carboxylic acid tert-butyl ester

- 5-Amino-1-(4-methylphenyl)-1H-pyrazole-4-carboxylic acid

- 4-Amino-1-methyl-4-piperidinecarboxylic acid

- 4-Amino-1-methylpiperidine-4-carboxylic acid hydrochloride

- 4-Amino-1-methyl-4-piperidinecarboxylic acid methyl ester

- 3-Amino-5-methylpyrazine-2-carboxylic acid

- 3-Amino-1-methyl-1h-pyrazole-4-carboxylic acid

- 3-Amino-1-methyl-1h-pyrazole-5-carboxylic acid

- 4-Amino-1-methyl-1h-pyrazole-3-carboxylic acid

- 4-Amino-3-methyl-1h-pyrazole-5-carboxylic acid

- 5-Amino-1-methyl-1h-pyrazole-3-carboxylic acid

- 4-Amino-1-methyl-1h-pyrazole-5-carboxylic acid hydrochloride

- 4-Amino-3-methyl-pyrazole-1-carboxylic acid tert-butyl ester

- 5-(Aminomethyl)pyrazolo[1,5-a]pyridine-3-carboxylic acid hydrochloride

- 7-Amino-2-methylpyrazolo[1,5-a]pyrimidine-6-carboxylic acid

- 7-Amino-3-methylpyrazolo[1,5-a]pyrimidine-6-carboxylic acid

- 2-Amino-4-methylpyridine-3-carboxylic acid

- 2-Amino-6-methyl-3-pyridinecarboxylic acid

- 3-Amino-2-methylpyridine-5-carboxylic acid

- 3-Amino-4-methylpyridine-2-carboxylic acid

- 3-Amino-5-methyl-pyridine-2-carboxylic acid amide

- 5-Amino-6-methyl-3-pyridinecarboxylic acid ethyl ester

- 5-Amino-2-methylpyridine-4-carboxylic acid hydrochloride

- 2-Amino-4-methyl-pyrimidine-5-carboxylic acid

- 4-Amino-6-methyl-pyrimidine-2-carboxylic acid methyl ester

- 4-Amino-1-methyl-1h-pyrrole-2-carboxylic acid hydrochloride

- 2-Aminomethyl-pyrrolidine-1-carboxylic acid benzyl ester

- 2-Amino-7-methyl-7h-pyrrolo[2,3-d]pyrimidin-6-carboxylic acid methyl ester

- 7-Amino-2-(methylsulfanyl)[1,2,4]triazolo[1,5-a]pyrimidine-6-carboxylic acid

- 3-(Aminomethyl)-1-[(tert-butoxy)carbonyl]azetidine-3-carboxylic acid hydrochloride

- 4-Aminomethyltetrahydropyran-4-carboxylic acid

- 4-(Aminomethyl)tetrahydro-2h-pyran-4-carboxylic acid methyl ester hydrochloride

- 2-Amino-5-methylthiophene-3-carboxylic acid

- 3-Amino-4-methylthiophene-2-carboxylic acid

- 4-Amino-5-methylthiophene-3-carboxylic acid

- 4-Amino-2-(methylthio)pyrimidine-5-carboxylic acid

- 7-Amino-2-methyl[1,2,4]triazolo[1,5-a]pyrimidine-6-carboxylic acid

- 5-Amino-1-methyl-3-(trifluoromethyl)-1h-pyrazole-4-carboxylic acid

- 2-Amino-3- nitrobenzonitrile

- 3-Amino-5-(3-nitro-phenyl)-thiophene-2-carboxylic acid ethyl ester

- 3-Amino-7-oxabicyclo[2.2.1]hept-5-ene-2-carboxylic acid hydrochloride

- 1-Amino-4-oxocyclohexanecarboxylic acid ethylene ketal

- 3-Amino-5-oxo-4,5-dihydro-pyrazine-2-carboxylic acid methyl ester

- 6-Amino-4-oxo-1,4-dihydroquinoline-2-carboxylic acid

- 2-Amino-4-oxo-1,5,7,8-tetrahydro-4h-pyrido[4,3-d]pyrimidine-6-carboxylic acid tert-butyl ester

- 4-(4-Aminophenethyl)piperazine-1-carboxylic acid tert-butyl ester

- 3-Amino-5-phenylbenzoic acid

- 2-(3-Aminophenyl)-6-bromoquinoline-4-carboxylic acid

- 2-(3-Aminophenyl)-6-chloroquinoline-4-carboxylic acid

- 2-(4-Aminophenyl)-6-chloroquinoline-4-carboxylic acid

- 1-(3-Amino-phenyl)-cyclopropanecarboxylic acid amide

- 2-(3-Aminophenyl)-6,8-dimethylquinoline-4-carboxylic acid

- 1-(3-Aminophenyl)-5-oxo-4,5-dihydro-1h-pyrazole-3-carboxylic acid

- 1-(4-Aminophenyl)-2-oxopyridine-3-carboxylic acid

- 4-Amino-1-phenyl-1h-pyrazole-3-carboxylic acid

- 5-Amino-1-phenyl-1h-pyrazole-4-carboxylic acid

- 2-Amino-4-phenylpyrimidine-5-carboxylic acid

- 2-(3-Aminophenyl)quinoline-4-carboxylic acid

- 2-(4-Amino-phenyl)-quinoline-4-carboxylic acid

- 3-Amino-5-phenylthiophene-2-carboxylic acid

- 4-Aminopiperidine-4-carboxylic acid

- 1-Aminopropan-2-one hydrochloride

- 4-(3-Amino-propionyl)-piperazine-1-carboxylic acid tert-butyl ester

- 1-(3-Aminopropyl)-5-tert-butyl-2-methylpyrrole-3-carboxylic acid

- 3-Amino-1H-pyrazole-5-carboxylic acid

- 5-Amino-1h-pyrazole-4-carboxylic acid

- 5-Amino-1h-pyrazole-3-carboxylic acid hydrochloride

- 5-Amino-pyrazole-1,4-dicarboxylic acid 1-tert-butyl ester 4-ethyl ester

- 2-Aminopyrazolo[1,5-a]pyrimidine-3-carboxylic acid

- 7-Aminopyrazolo[1,5-a]pyrimidine-6-carboxylic acid

- 3-(5-Amino-1h-pyrazol-3-yl)-azetidine-1-carboxylic acid tert-butyl ester

- 5-Amino-pyridazine-4-carboxylic acid

- 6-Aminopyridazine-3-carboxylic acid

- 6-Aminopyridine-2-carboxylic acid ethyl ester

- 4-Aminopyridine-2-carboxylic acid monohydrate

- 4-Aminopyridine-2,6-dicarboxylic acid

- 4-(6-Amino-pyridin-3-yloxy)-pyridine-2-carboxylic acid methylamide

- 5-Amino-pyrimidine-4-carboxylic acid

- 3-Amino-pyrrolidine-1,3-dicarboxylic acid 1-tert-butyl ester

- 5-Amino-1h-pyrrolo[2,3-b]pyridine-2-carboxylic acid

- 2-Amino-7h-pyrrolo[2,3-d]pyrimidin-5-carboxylic acid

- 2-Amino-7h-pyrrolo[2,3-d]pyrimidin-6-carboxylic acid

- 2-Amino-7h-pyrrolo[2,3-d]pyrimidin-5-carboxylic acid methyl ester

- 2-Amino-7h-pyrrolo[2,3-d]pyrimidin-6-carboxylic acid methyl ester

- 4-Amino-7h-pyrrolo[2,3-d]pyrimidine-5-carboxylic acid

- 2-Aminoquinoline-3-carboxylic acid

- 2-Aminoquinoline-6-carboxylic acid

- 3-Aminoquinoline-5-carboxylic acid

- 3-Aminoquinoline-6-carboxylic acid

- 3-Aminoquinoline-7-carboxylic acid

- 3-Aminoquinoline-8-carboxylic acid

- 4-Aminoquinoline-6-carboxylic acid

- 5-Aminoquinoline-3-carboxylic acid

- 7-Aminoquinoline-5-carboxylic acid

- 3-Amino-1-(tert-butoxycarbonyl)-3-azetidinecarboxylic acid

- 5-Amino-2,3,4,5-tetrahydro-benzo[b]azepine-1-carboxylic acid tert-butyl ester

- 2-Amino-4,5,6,7-tetrahydrobenzo[b]thiophene-3-carboxylic acid

- 2-Amino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid isopropyl ester

- 2-Amino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid methyl ester

- 2-Amino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid tert-butyl ester

- 3-Aminotetrahydrofuran-3-carboxylic acid

- 3-Aminotetrahydro-3-furancarboxylic acid butyl ester

- 1-Amino-1,2,3,4-tetrahydro-1-naphthalenecarboxylic acid hydrochloride

- 2-Amino-1,2,3,4-tetrahydro-naphthalene-2-carboxylic acid hydrochloride

- 3-Amino-5,6,7,8-tetrahydrothieno[2,3-b]quinoline-2-carboxylic acid

- 3-Amino-tetrahydro-thiophene-3-carboxylic acid

- 2-Amino-6h-[1,3,4]thiadiazine-5-carboxylic acid ethyl ester hydrochloride

- 2-Amino-6h-1,3,4-thiadiazine-5-carboxylic acid hydrochloride

- 4-Aminothieno[3,2-d]pyrimidine-7-carboxylic acid

- 5-Aminothieno[2,3-d]pyrimidine-6-carboxylic acid

- 4-Aminothiophene-2-carboxylic acid

- 3-Aminothiophene-2-carboxylic acid potassium salt

- 3-Amino-thiophene-2-carboxylic acid sodium salt

- 3-Amino-3- thioxopropanamide

- 6-Amino-[1,2,4]triazine-5-carboxylic acid

- 5-Amino-4h-1,2,4-triazole-3-carboxylic acid

- 3-Amino[1,2,4]triazolo[4,3-a]pyridine-6-carboxylic acid

- 7-Amino[1,2,4]triazolo[1,5-a]pyrimidine-6-carboxylic acid

- 6-(5-Amino-1h-1,2,4-triazol-3-yl)cyclohex-3-ene-1-carboxylic acid

- Amino-tri-(carboxyethoxymethyl)- methane

- 4-Amino-3,5,6-trichloropyridine-2-carboxylic acid

- 5-Amino-1-[4-(trifluoromethoxy)phenyl]-1h-pyrazole-4-carboxylic acid

- 2-Amino-3,3,3-trifluoropropanoic acid hydrochloride

- 2-[(3-Amino-2,4,6-triiodophenyl)methyl]butanoic acid

- (1R,2R,3S,5R)-2-Amino-2,6,6-trimethyl-bicyclo[3.1.1]heptane-3-carboxylic acid methyl ester hydrochloride

- Ammonium adipate

- Ammonium 2-(1,3-benzodioxol-5-yloxy)-2-methylpropanoate

- Ammonium carbamate

- Ammonium citrate dibasic

- Ammonium dodecanedioate

- Ammonium ([2-(2-furyl)cyclohexyl]oxy)acetate

- Ammonium hydrogen maleate

- Ammonium succinate

- Amphotericin b

- Angelic acid

- Angelic acid isoamyl ester

- Angelic acid isobutyl ester

- Angelic anhydride

- 1,5-Anhydro-3-o-benzoyl-4,6-o-benzylidene-2-deoxy- 2-(n4-benzoylcytidin-1-yl)-d-altro-hexitol

- 2-Anilinobenzoic acid methyl ester

- 1[(Anilinocarbonyl)amino]cyclopropanecarboxylic acid

- 4-[5-(Anilinocarbonyl)-1,3,4-thiadiazol-2-yl]butanoic acid

- 3-[5-(Anilinocarbonyl)-1,3,4-thiadiazol-2-yl]propanoic acid

- 2-Anilinonicotinic acid

- Ansamitocin p 3'

- 1-Anthracenecarboxylic acid

- 2-Anthracenecarboxylic acid

- 9-Anthracenecarboxylic acid

- (1R,2R)-2-(Anthracene-2,3-dicarboximido) cyclohexanecarboxylic acid

- (1S,2S)-2-(Anthracene-2,3-dicarboximido) cyclohexanecarboxylic acid

- 9-Anthracenylmethyl acrylate

- 9-Anthracenylmethyl methacrylate

- Anthraquinone-2-carboxylic acid

- Anthraquinone-2,3-dicarboxylic acid

- Anti-3-oxotricyclo[2.2.1.0(2,6)]heptane-7-carboxylic acid

- D-Araboascorbic acid

- Arachidic acid

- Arachidic acid ethyl ester

- Arachidic acid methyl ester

- Arachidic anhydride

- (3Ar*,6ar*)-benzylhexahydropyrrolo [3,2-b]pyrrole-1(2h)-carboxylate

- (3S,3Ar,5r,6ar,7r)-6-iodo-2-oxooctahydro-3,5-methanocyclopenta[b]pyrrole-7-carboxylic acid

- (4Ar,8ar)-rel-1-methyl-decahydro-1,5-naphthyridine, oxalic acid

- (3aR,6aR)-tert-butyl hexahydropyrrolo[3,4-b]pyrrole-1(2H)-carboxylate

- (3aR,6aR)-tert-butyl hexahydropyrrolo[3,4-b]pyrrole-5(1H)-carboxylate

- (4Ar,9ar)-tert-butyl octahydro-[1,4]oxazino[3,2-c]azepine-4(4ah)-carboxylate

- (3R,4aR,5S,6S,6aS,10S,10aR,10bS)-6,10,10b-Trihydroxy-3,4a,7,7,10a-pentamethyl-1-oxo-3-vinyldodecahydro-1H-benzo[f]chromen-5-yl acetate

- (3S,3Ar,5s,6as,7s)-2-oxooctahydro-3,5-methanocyclopenta[b]pyrrole-7-carboxylic acid

- (3Ar,5s,6as)-tert-butyl 5-hydroxyhexahydrocyclopenta [c]pyrrole-2(1H)-carboxylate

- (3Ar,6as)-tert-butyl 5-oxohexahydrocyclopenta [c]pyrrole-2(1h)-carboxylate

- (4Ar,7as)-tert-butyl tetrahydro-2h-[1,4]dioxino[2,3-c]pyrrole-6(3h)-carboxylate

- Ar-13324 hydrochloride

- (1S,7S,8S,8aR)-8-(2-((2R,4R)-4-Hydroxy-6-oxotetrahydro-2H-pyran-2-yl)ethyl)-7-methyl-1,2,3,7,8,8a-hexahydronaphthalen-1-yl (S)-2-methylbutanoate

- (3S,11Ar)-6-methoxy-3-methyl-5,7-dioxo-2,3,5,7,11,11a-hexahydrooxazolo[3,2-d]pyrido[1,2-a]pyrazine-8-carboxylic acid

- (9Ar)-octahydro-1h-pyrido[1,2-a]piperazine oxalic acid

- (6S,8Ar)-3-oxooctahydroindolizine-6-carboxylic acid

- (3aS,9aR,10aR,10bS,E)-6,9a- Dimethyl-3-methylene-3a,4,5,8,9,9a,10a,10b-octahydrooxireno[2',3':9,10]cyclodeca[1,2-b]furan-2(3H)-one

- (3As,4r,5s,6ar)-(+)-hexahydro-5-hydroxy- 4-(hydroxymethyl)-2h-cyclopenta[b]furan-2-one

- (3As,4s,6ar)-4-methoxytetrahydrofuro [3,4-b]furan-2(3h)-one

- (1R,4As,10ar)-methyl 7-isopropyl-1,4a-dimethyl-1,2,3,4,4a,9,10,10a-octahydrophenanthrene-1-carboxylate

- (2R,3aS,6S,6aS,7R,10R,11aR,11bS)-2-(Furan-3-yl)- 11b-methyloctahydro-4H-3a,6:7,10-dimethanofuro[2,3-c]oxepino[4,5-e]oxepine-4,8(6H)-dione

- (3As,5r,6s,6as)-6-hydroxy-2,2-dimethyltetrahydrofuro[2,3-d][1,3]dioxole-5-carboxylic acid Synonyms : (3aS,5R,6S,6aS)-6-hydroxy-2,2-dimethyltetrahydrofuro[2,3-d][1,3]dioxole-5-carboxylic acid

- (4As,8as)-tert-butyl hexahydro-1h-pyrido[3,4-b][1,4]oxazine-6(7h)-carboxylate

- (3As*,6as*)-tert-butylhexahydropyrrolo [3,4-c]pyrrole-2(1H)-carboxylate

- (3aS,6aS)-tert-butyl hexahydropyrrolo[3,4-b]pyrrole-5(1H)-carboxylate

- L-Ascorbic acid

- L-Ascorbic acid 2-phosphate sesquimagnesium salt hydrate

- L-Ascorbyl 2,6-dibutyrate

- L-Ascorbyl 2,6-dipalmitate

- (4R,12As)-7-methoxy-4-methyl-6,8-dioxo-3,4,6,8,12,12a-hexahydro-2h-pyrido[1',2':4,5]pyrazino[2,1-b][1,3]oxazine-9-carboxylic acid

- (9As)-octahydro-1h-pyrido[1,2-a]piperazine, oxalic acid

- Atractyloside potassium salt

- Atracurium oxalate

- Atropic acid

- 7- Geranyloxycoumarin

- Aurintricarboxylic acid

- AVERMECTIN B1A

- 7-Azabicyclo[2.2.1]heptane-2-carboxylic acid ethyl ester hydrochloride

- (1R*,2S*,4S*)-7-Aza-bicyclo[2.2.1]heptane-2-carboxylic acid hydrobromide

- 2-Azabicyclo[2.2.1]heptane-6-carboxylic acid hydrochloride

- 2-Azabicyclo[3.1.1]heptane-1-carboxylic acid hydrochloride

- 3-Azabicyclo[3.1.1]heptane-1-carboxylic acid hydrochloride

- 3-Azabicyclo[4.1.0]heptane-6-carboxylic acid hydrochloride

- 3-Azabicyclo[4.1.0]heptane-3-carboxylic acid, 6-(hydroxymethyl)-, 1,1-dimethylethyl ester